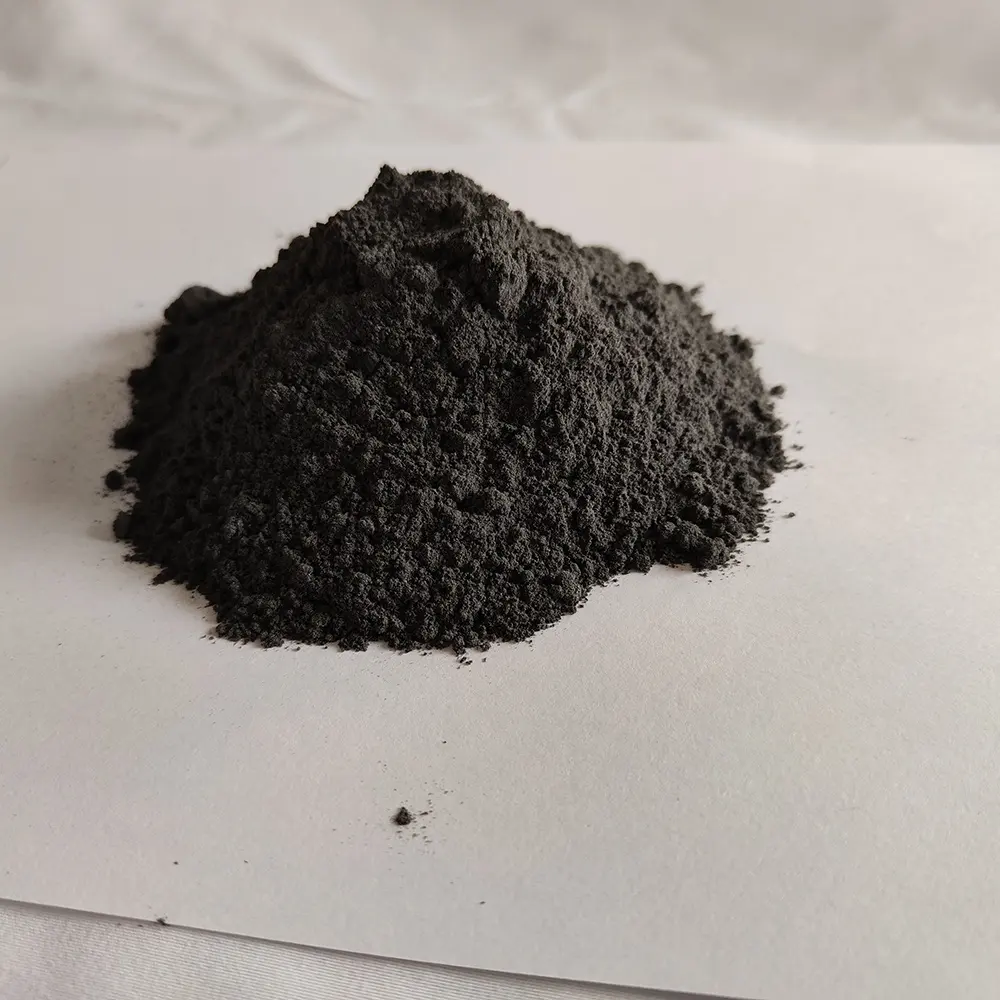

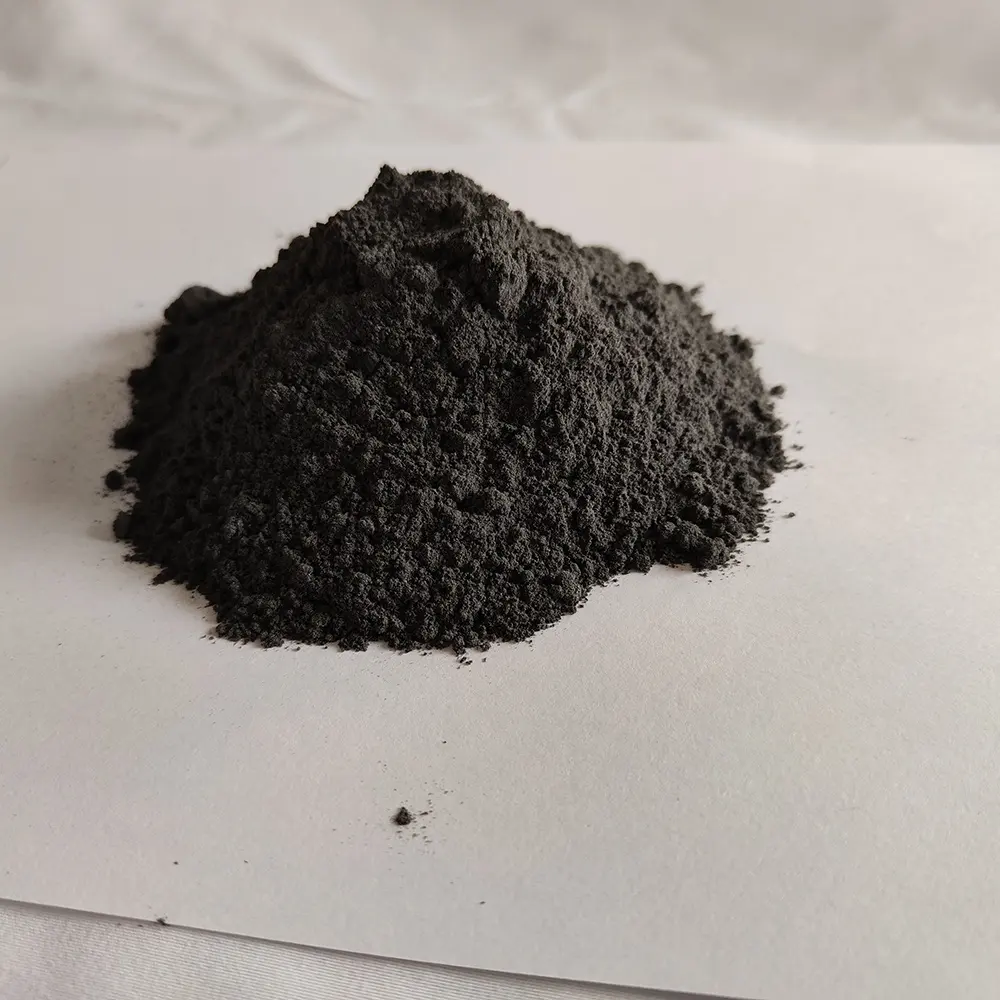

Powdered PEEK (polyether ether ketone) is a high - performance engineering thermoplastic material used in the production of bearing cage2. Here is an overview of its relevant information:

High - temperature resistance: It can withstand extreme operating conditions without losing mechanical integrity, making it suitable for applications involving elevated temperatures or thermal cycling.

Low friction and wear: The material has an inherently low coefficient of friction, which helps reduce wear and friction within the bearing assembly, ensuring smooth and efficient operation, minimizing energy consumption, and extending the overall service life of the bearings.

Excellent mechanical strength: PEEK bearing cages exhibit high mechanical strength and stiffness, providing robust support to the rolling elements within the bearing, which contributes to enhanced load - bearing capacity, allowing the bearings to endure heavy loads and harsh operating environments.

Chemical resistance: PEEK is highly resistant to various chemicals, including acids, bases, and solvents. This property protects the bearing cages from corrosion and degradation when exposed to aggressive substances, making them suitable for applications in chemically challenging environments.

Lightweight: It is beneficial for reducing the overall weight of machinery and equipment, which is especially crucial in industries such as aerospace and automotive, where weight reduction can lead to improved fuel efficiency and overall performance.

Dimensional stability: PEEK maintains its dimensional stability even in extreme conditions, ensuring that the bearing cages retain their shape and form over time, which is vital for precision engineering applications that demand tight tolerances and consistent performance.

Powdered PEEK can be processed into bearing cages through injection molding or CNC machining2. Injection molding is suitable for mass - producing bearing cages with complex shapes, while CNC machining is used to produce high - precision bearing cages with tight tolerances.

The PEEK bearing cage is widely used in various industries, including aerospace, automotive, industrial machinery, oil and gas, medical devices, and food processing. For example, in the aerospace industry, it is used in aircraft engines, landing gear, and control systems; in the automotive industry, it is applied to high - performance engines, transmissions, and suspension systems.

The basic properties of peek Bearing cage material:

| Model Number | LY-202-1 |

| ENTRY NAME | UNIT | INDEX |

| Friction Coefficient |

| 0.209 |

| Wear Scar Width | mm | 4.98 |

| Volume Wear | cm³ | 3.5×10³ |

| Tensile Strength | MPa | 74 |

| Bending Strength | MPa | 120 |

| Impact strength (without notches) | KJ/㎡ | 17 |

| Maximum operating temperature | ℃ | 260 |

Advantages of PEEK Bearing cage material

1. Bearing cage material can resist the erosion of various chemical substances and remain stable in complex chemical environments.

2.Bearing cage material is less affected by factors such as temperature and humidity.

3. The use of Bearing cage material helps reduce friction and energy loss during bearing operation.

Logistics and Freight Capacity:

Our commitment to shipping within 7 days demonstrates a deep understanding of our customers' time sensitivity. In the fiercely competitive market, we respond quickly to customer needs through efficient logistics operations and technological support to ensure that orders are delivered on time in the shortest possible time.