PEEK (Polyetheretherketone) material, leveraging its outstanding comprehensive properties, has become a key alternative to traditional materials (such as PTFE, metal, PA, PPS, etc.) in the pump and valve sealing field. It is particularly suitable for harsh operating conditions involving high temperature, high pressure, strong corrosion, and high cleanliness requirements.

I. Core Application Scenarios

The application of PEEK in pump and valve sealing is very extensive, mainly covering the following scenarios:

Petrochemical and Energy Industry:

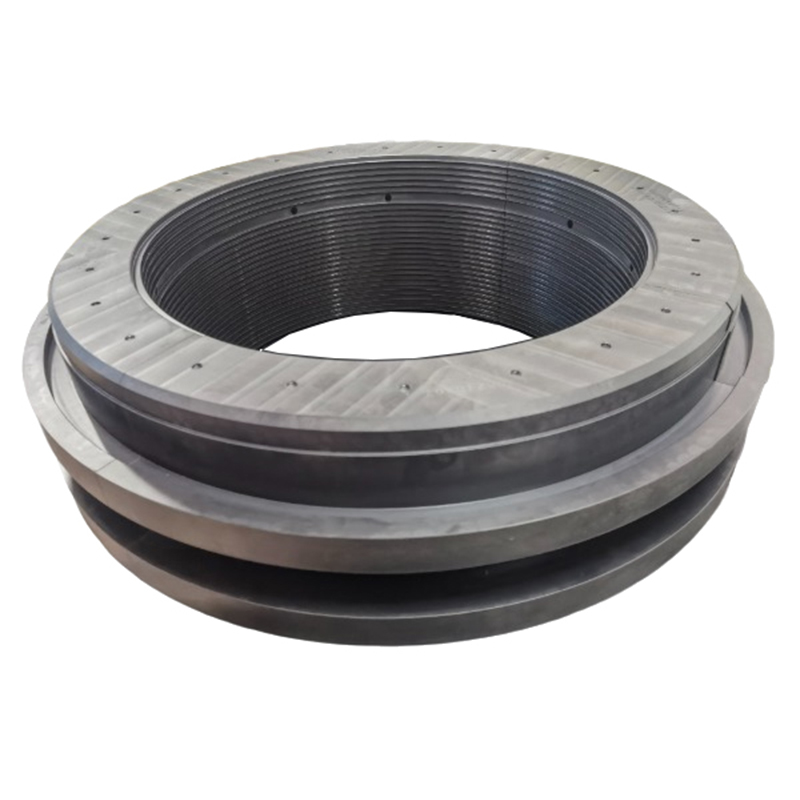

Application Components: Sealing rings for oil and gas pipelines, downhole tool seals, valve seals (e.g., ball valves, control valves), pump sealing rings (e.g., submersible electric pumps), compressor valve plates, etc.

Operating Condition Characteristics: The medium often contains highly corrosive components such as hydrogen sulfide, carbon dioxide, and brine, and operates in high-temperature and high-pressure environments.

Document Basis: Multiple documents explicitly state that PEEK seals can effectively withstand corrosive media in crude oil, maintain dimensional stability and sealing performance under high temperature and pressure, and have a service life far exceeding traditional materials like PTFE. In the oil and gas field, PEEK is gradually replacing PTFE as the material for sealing rings.

Chemical Process Industry:

Application Components: Chemical pumps and valves, reactor seals, pipeline connectors, corrosion-resistant filter elements, etc.

Operating Condition Characteristics: Contact with various chemicals such as strong acids, strong alkalis, and organic solvents, requiring extremely high chemical inertness and purity from the material.

Document Basis: PEEK exhibits excellent chemical resistance; typically, only concentrated sulfuric acid can dissolve or damage it, and its corrosion resistance is comparable to nickel steel. Its self-lubricating properties eliminate or reduce the need for lubricating oil, fundamentally avoiding contamination of the reaction medium by lubricants.

General Machinery and High-End Manufacturing:

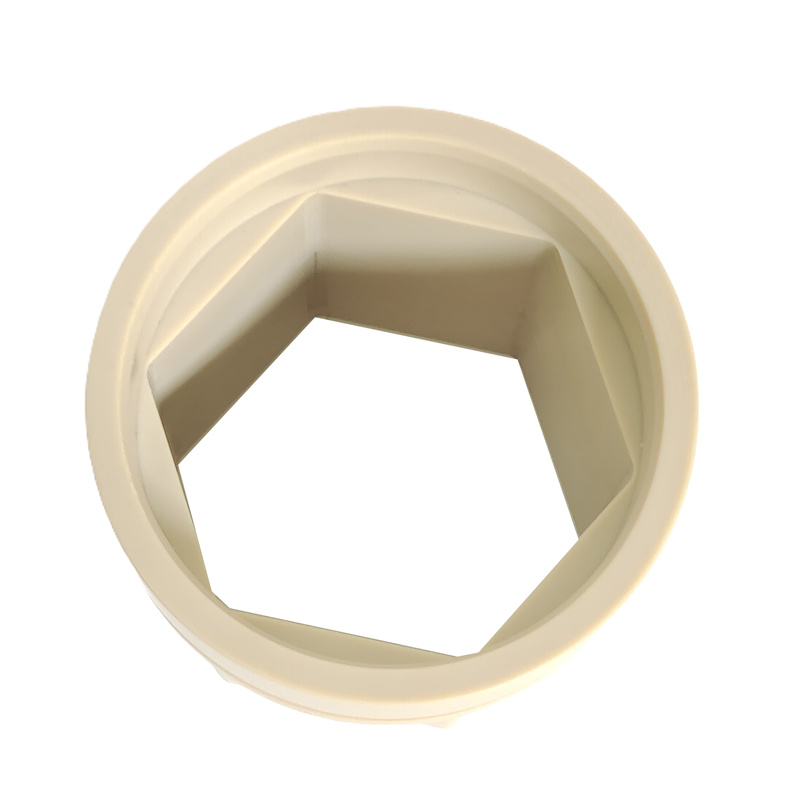

Application Components: Industrial valves, hydraulic system seals, bearing seals, vacuum pump seals, etc.

Operating Condition Characteristics: Requirements for wear resistance, fatigue resistance, long service life, and operation possibly accompanied by high temperatures or corrosive environments.

Document Basis: PEEK combines excellent rigidity, toughness, and fatigue resistance, with good wear resistance (friction coefficient as low as 0.1-0.4). It can maintain performance at temperatures up to 250°C, making it suitable for high-load, high-wear scenarios.

General Machinery and High-End Manufacturing:

Application Components: Industrial valves, hydraulic system seals, bearing seals, vacuum pump seals, etc.

Operating Condition Characteristics: Requirements for wear resistance, fatigue resistance, long service life, and operation possibly accompanied by high temperatures or corrosive environments.

Document Basis: PEEK combines excellent rigidity, toughness, and fatigue resistance, with good wear resistance (friction coefficient as low as 0.1-0.4). It can maintain performance at temperatures up to 250°C, making it suitable for high-load, high-wear scenarios.

II. Performance Advantages and Substitution Rationale

The substitution of other materials by PEEK in the pump and valve sealing field is primarily based on the following performance advantages:

Exceptional Chemical Corrosion Resistance: Resistant to most acids, alkalis, hydrocarbons, and solvents, with performance close to nickel steel, far exceeding that of ordinary engineering plastics. This makes it an ideal upgraded alternative to PTFE in the chemical and oil & gas fields.

Outstanding High-Temperature Resistance: Long-term service temperature up to 260°C, capable of withstanding over 300°C short-term, with a high load heat deflection temperature. This ensures that seals do not soften or fail in high-temperature fluids or environments.

Excellent Mechanical Properties and Dimensional Stability: High strength, high rigidity, coupled with good toughness. Outstanding creep resistance and fatigue resistance under alternating stress and long-term pressure, maintaining tight contact of sealing surfaces to prevent leakage.

Low Friction and Self-Lubrication: Low friction coefficient with self-lubricating effects. This characteristic makes it particularly suitable for applications where lubricating oil cannot or should not be used (e.g., food, pharmaceuticals, high-purity chemicals), and it reduces wear, extending seal life.

Extremely Low Moisture Absorption and Hydrolysis Resistance: Saturated water absorption rate at 23°C is only 0.4%, and performance remains stable in high-temperature, high-pressure steam and hot water. Avoids dimensional changes and sealing failure due to water absorption expansion, suitable for steam systems and humid environments.

High Purity and Low Outgassing: Clean processing, suitable for pump and valve seals in industries with extremely high cleanliness requirements, such as semiconductors and pharmaceuticals.

Overcoming Defects of Traditional Materials: Documents specifically point out that traditional oil pipeline sealing material PTFE (Polytetrafluoroethylene), even when composite-reinforced, still suffers from issues like rapid wear, cold flow (creep), and easy fracture under high temperature and pressure. PEEK sealing rings overcome these shortcomings while maintaining corrosion resistance comparable to PTFE, making them an ideal upgraded material.

III. Typical Application Cases

Specific application cases of PEEK in pump and valve sealing include:

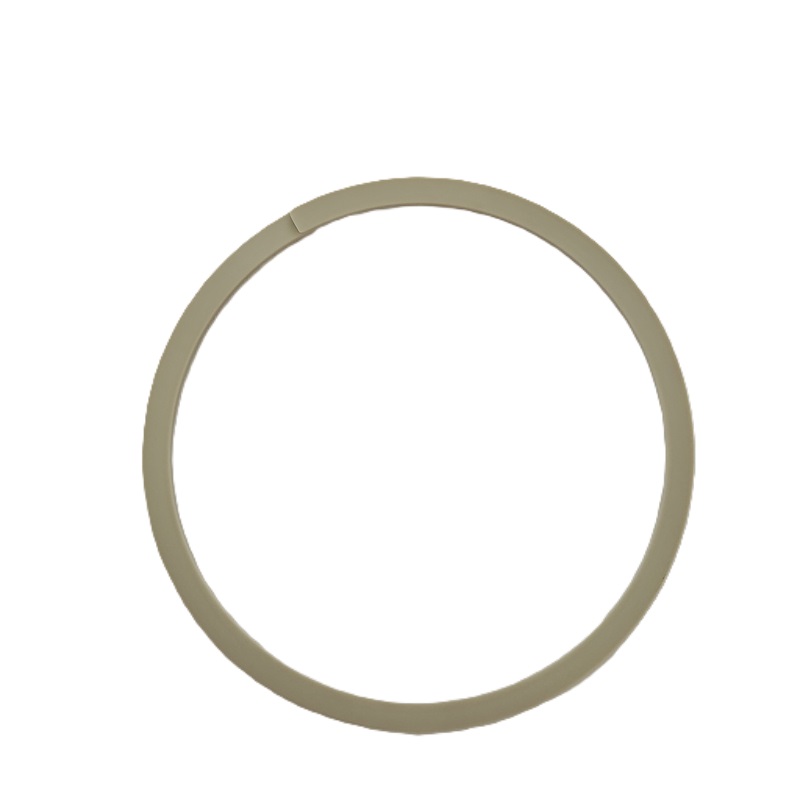

Oil pump seals, 3-shaped seals, pump and valve sealing rings.

Valves, pump bodies, bearings, and seals for chemical pumps and valves.

Sealing components for cryogenic ball valves and thermoplastic composite pipes in sub-salt oil fields.

Used as compressor valve plates, piston rings, and various seals in mechanical equipment.

IV. Related Companies

III. Typical Application Cases

Specific application cases of PEEK in pump and valve sealing include:

Oil pump seals, 3-shaped seals, pump and valve sealing rings.

Valves, pump bodies, bearings, and seals for chemical pumps and valves.

Sealing components for cryogenic ball valves and thermoplastic composite pipes in sub-salt oil fields.

Used as compressor valve plates, piston rings, and various seals in mechanical equipment.

IV. Related Companies

Companies providing PEEK materials or products in the pump and valve sealing field include:

Victrex (UK): A global leader in PEEK, whose high-performance solutions are applied in demanding sealing environments for oil exploration.

Dalian Luyang Technology Development Co., Ltd.: Specializes in producing modified PEEK materials and products. Products such as PEEK bolts, cable ties, and seals are directly applied in scenarios like oil pumps and valves.

V. Summary

In summary, PEEK material, due to its unique combination of properties—corrosion resistance, high temperature and pressure resistance, wear resistance, self-lubrication, and dimensional stability—addresses the performance bottlenecks of traditional materials under extreme operating conditions in the pump and valve sealing field. It not only significantly improves the reliability and service life of seals, reducing maintenance costs, but also meets the cleanliness and contamination-free requirements of special industries (such as semiconductors, pharmaceuticals, and food). With the trends of "replacing steel with plastics" and the localization of high-end equipment, the penetration rate of PEEK in this critical basic component field of pump and valve sealing is expected to continue increasing.