A PEEK (Polyether Ether Ketone) bushing/PEEK sliding bearing is a cylindrical - shaped component made from PEEK, a high - performance thermoplastic polymer. PEEK has exceptional mechanical, chemical, and thermal properties, making it an ideal material for manufacturing bushings in various applications.

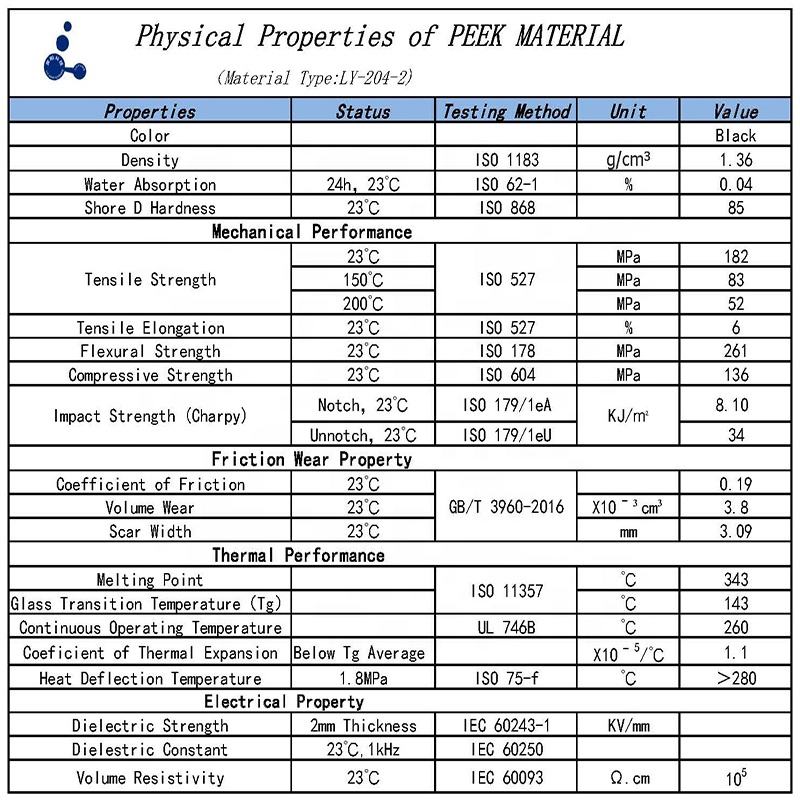

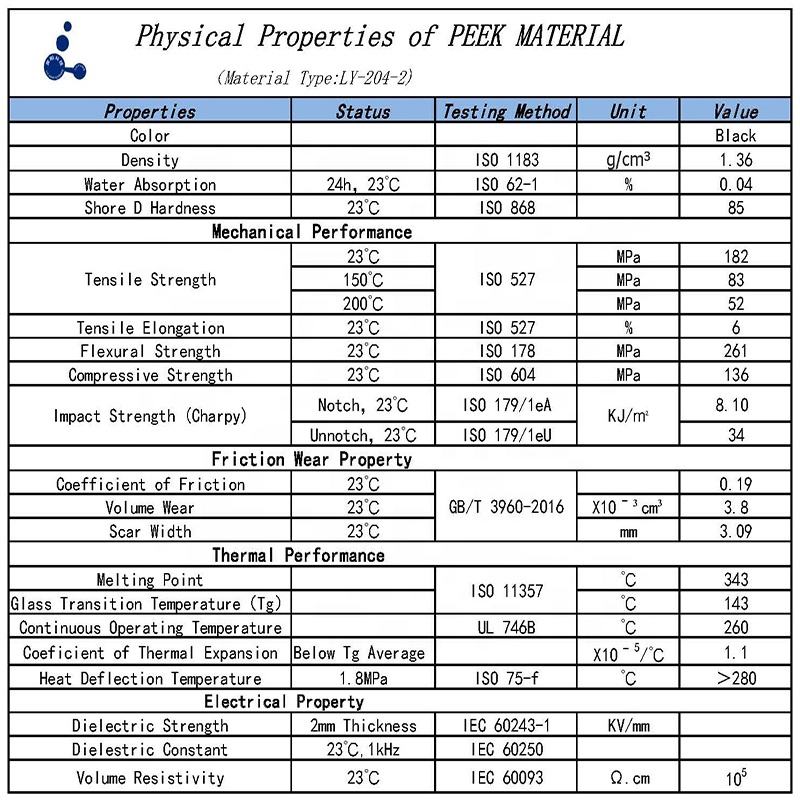

Properties of PEEK

PEEK can withstand continuous operating temperatures up to 260°C (500°F) and short - term exposure to even higher temperatures. This makes PEEK bushings/PEEK sliding bearing suitable for use in environments where traditional materials would fail due to heat, such as in automotive engines or industrial furnaces.

It resists a wide range of chemicals, including acids, alkalis, and organic solvents. This property ensures that PEEK bushings/PEEK sliding bearing maintain their integrity and functionality in harsh chemical environments, like those found in the chemical processing industry.

PEEK has a high tensile strength and good fatigue resistance. PEEK bushings/PEEK sliding bearing can endure heavy loads and repetitive mechanical stresses without significant deformation or failure, which is crucial in applications such as aerospace and high - performance machinery.

The material has a low coefficient of friction, reducing wear and tear between moving parts. In gear pump systems, for example, a PEEK bushing can be used to support the rotating shafts. Its low friction property helps to improve the efficiency of the pump by reducing the energy required to overcome friction, thus saving energy and extending the lifespan of the pump components.

Applications of PEEK Bushings

PEEK bushings can be used to replace traditional metal or rubber bushings in gear pumps. Their chemical resistance is beneficial when pumping aggressive fluids. Also, the low friction and high - temperature resistance properties contribute to smoother operation and longer service life, even under demanding conditions.

In aircraft engines and other aerospace components, PEEK bushings are used due to their lightweight nature (compared to metal counterparts) and high - temperature resistance. They help in reducing the overall weight of the aircraft while maintaining high - performance standards.

PEEK's biocompatibility makes it suitable for use in medical devices. PEEK bushings can be found in equipment such as surgical instruments, where their chemical resistance and durability are essential for repeated sterilization processes.

Advantages of PEEK Sleeve Bushing:

PEEK Sleeve Bushing,PEEK Flamed Bush ,is lighter than traditional metal bushings, making it easier to transport and operate.

PEEK Sleeve Bushing,PEEK Flamed Bush has a flexible design, fast installation, and is easy to integrate into various mechanical equipment.

PEEK Sleeve Bushing,PEEK Flamed Bush has a long lifespan and low maintenance cost.

Details of PEEK sliding bearing:

Application of PEEK Flamed Bush:

PEEK Sleeve Bushing is applied in the aerospace field, such as aircraft engines, navigation systems, etc.

PEEK Sleeve Bushing is used in the fields of oil, natural gas, and nuclear energy to manufacture valves, pumps, and other critical components.

As a supporting component in precision pump products, PEEK Sleeve Bushing provides high-precision and long-life support.

Why did you choose us?

We have rich production experience and professional production equipment, which can provide customers with high-quality PEEK Sleeve Bushing.

We have a professional customer service team and technical support team that can quickly respond to various customer needs and issues.

We provide customized services and can customize PEEK shaft sleeve products with different sizes and performance according to customer needs and specifications.