Function

The gear pump seal stop strip / PEEK sealing strip/PEEK seal stop strip serves to prevent the leakage of fluids or media within the gear pump from the sealing area. It maintains the system's tightness, preventing oil leakage that could lead to environmental pollution, resource waste, and adverse effects on equipment operation.

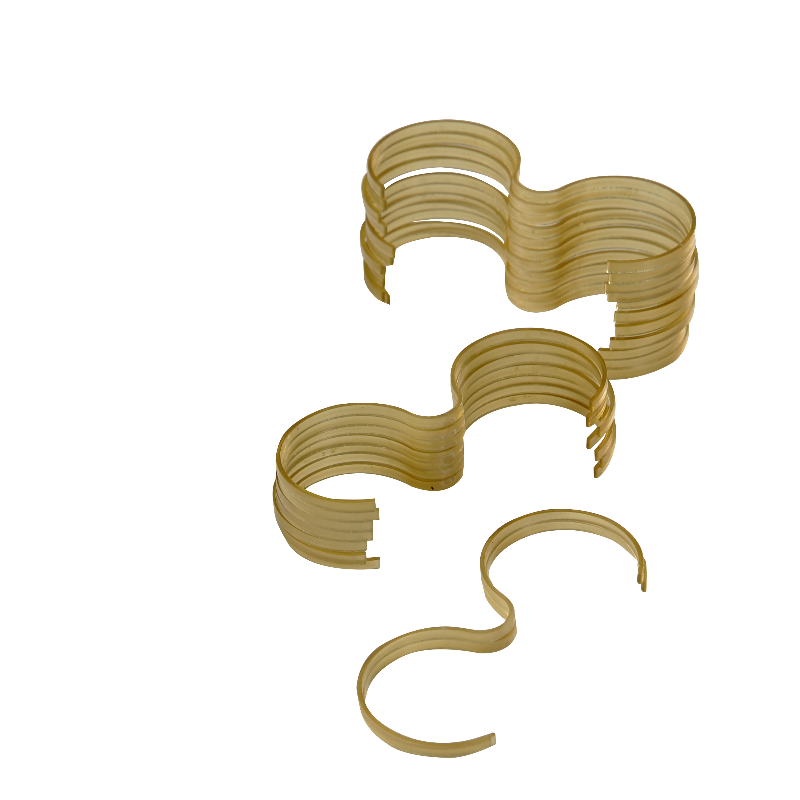

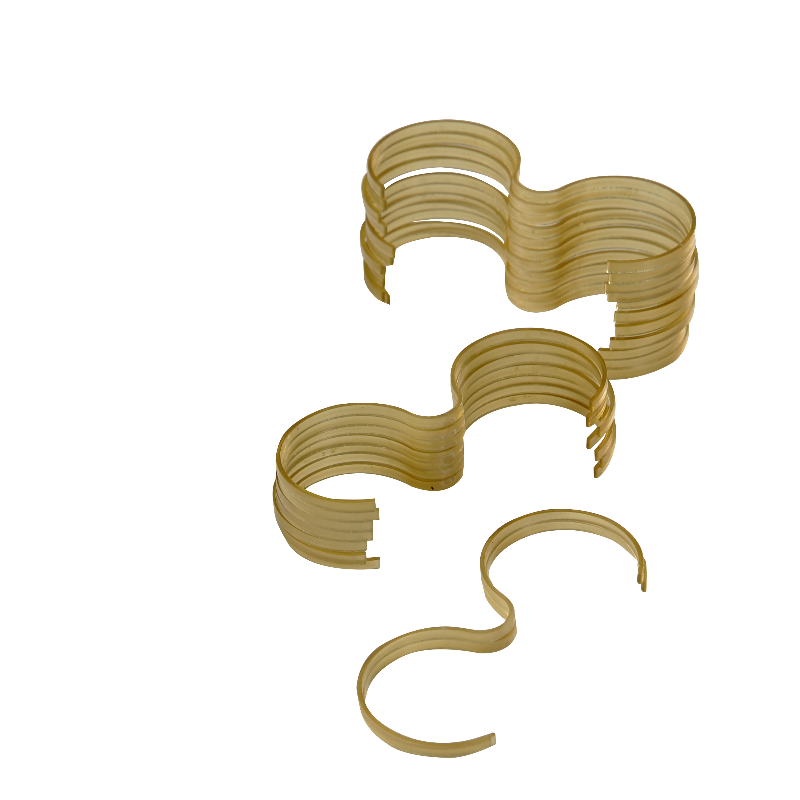

In high - pressure gear pumps, for example, an "L"-shaped seal stop strip can enclose the axial and radial ends of a "W"-shaped gasket, shielding it from the impact of high - pressure media oil. This protection helps prevent gasket damage, corrosion, and even failure.

By working in tandem with components like gaskets, the stop strip reduces gaps, improving the reliability of the seal. This is conducive to maintaining the operating efficiency of the gear pump and ensuring its normal operation.

Structure and Types

In the sealing device of high - pressure gear pumps, the high - pressure seal stop strip consists of mutually perpendicular axial and radial protective walls. It can semi - surround the gasket, protecting its axial and radial ends.

In some gear pump sealing assemblies, the metal stop strip is placed on the second - step plane of a stepped sealing ring. Its thickness is less than the height difference between the first - step plane and the second - step plane, working in coordination with the sealing ring to achieve sealing.

Material Selection

Materials such as stainless steel are characterized by high strength, wear resistance, and corrosion resistance. They are suitable for high - pressure, high - temperature, and applications with stringent sealing requirements, capable of withstanding significant pressure and impact forces.

These materials offer good flexibility, elasticity, and sealing properties. They can adapt to a certain degree of deformation and vibration. They are commonly used in the sealing systems of low - pressure and normal - temperature gear pumps, with relatively low costs and convenient installation.

Advantages of Gear pump seal stop strip / PEEK sealing strip/PEEK seal stop strip :

1.PEEK sealing strip can maintain stable performance at higher temperatures, with strong resistance to deformation and degradation.

2.PEEK sealing strip has excellent wear resistance, can withstand large friction, and has a significant anti wear effect.

3. Thanks to its high temperature resistance, wear resistance, and chemical stability, PEEK seal stop strip has a longer service life, which helps to reduce maintenance costs.

Application of Gear pump seal stop strip / PEEK sealing strip/PEEK seal stop strip :

1. In the aerospace field, PEEK seal stop strip/PEEK sealing strip is used for sealing hydraulic and pneumatic systems of high-speed aircraft such as airplanes and rockets due to its high temperature resistance, corrosion resistance, and other characteristics.

2. In the pharmaceutical industry, due to its high cleanliness, non toxicity, and corrosion resistance, PEEK 3-shaped sea is used for sealing various pharmaceutical equipment.

3. PEEK seal stop strip / PEEK sealing strip can also be applied in fields such as metallurgy, nuclear energy, and shipbuilding, providing reliable sealing solutions.

Why choose us:

We have a professional production and research and development team that can provide customized products and services according to customer needs.

We provide customers with fast response service support, and customers receive timely technical support and solutions during use.