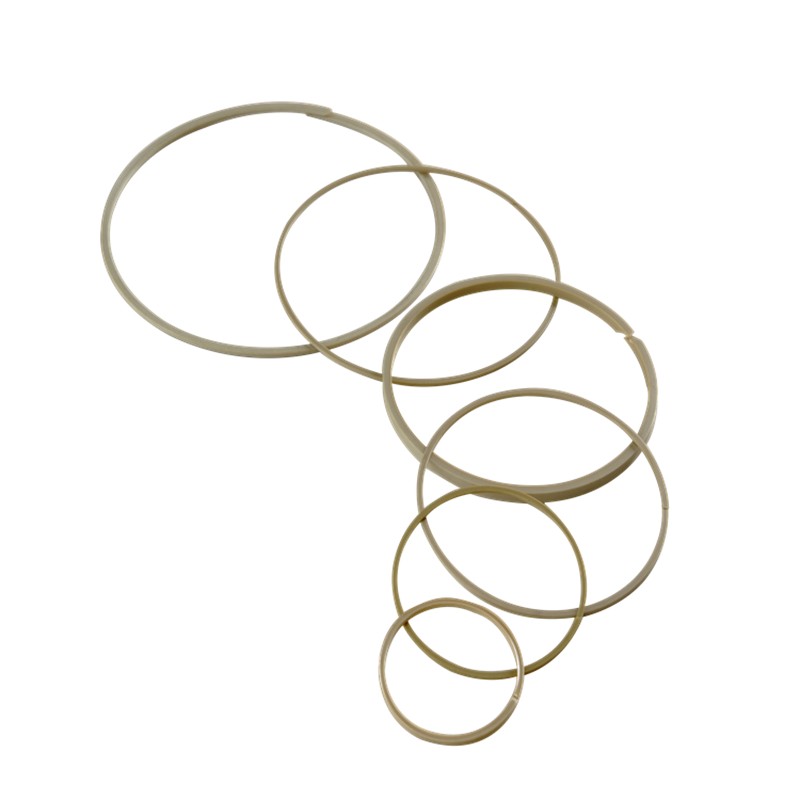

Product Advantages of Peek Retaining Ring.

Our PEEK retainer ring(PEEK Back-up ring/PEEK Check ring/PEEK detent ring) material is heat-treated to ensure good dimensional stability and no overlap at the cutout.Peek Retaining Ring is also made of PEEK retaining ring, which is a special engineering plastic with excellent physical and chemical properties such as resistance to high temperatures and chemicals.Peek Retaining Ring has high strength, rigidity and hardness as well as excellent fatigue resistance compared to ordinary retaining rings. The PEEK retainer ring(PEEK Back-up ring/PEEK Check ring/PEEK detent ring) offers high strength, rigidity and stiffness, as well as excellent fatigue resistance compared to conventional retaining rings. Its load heat deflection temperature of up to 316°C means that it maintains good mechanical properties in high temperature environments. The PEEK retainer ring(PEEK Back-up ring/PEEK Check ring/PEEK detent ring) outperforms ordinary retaining rings in a wide range of applications and is favoured by most customers.

Peek Retaining Ring Considerations:

1. Installation force: Avoid excessive force when installing the PEEK retainer ring(PEEK Back-up ring/PEEK Check ring/PEEK detent ring) to avoid deformation or damage to the retaining ring. For example, control the pressure when using tools to install and prevent excessive force.

2. Size matching: Make sure that the size of the PEEK retainer ring(PEEK Back-up ring/PEEK Check ring/PEEK detent ring)matches the size of the installation part accurately. If the size is too small, it may not play an effective blocking role, while if the size is too large, it may be difficult to install or affect the normal operation of the equipment.

3. Temperature conditions: Consider the temperature of the working environment. Although PEEK has good high temperature resistance, if it is in an environment beyond its recommended temperature range for a long time, it may affect its performance and service life.

About Us:

Dalian Luyang Technology Development Co., Ltd. was established in June 2006 and is a national high-tech enterprise. The company is located at No. 1-3 Baoling Street, Dalian Economic and Technological Development Zone, covering an area of 7500m2 and a building area of 12000m2. It has a modern factory and R&D center. Its products are widely used in electronics, aerospace, military industry, petrochemical industry, automobiles, mechanical equipment, various seals and other fields. The company's strong R&D team and excellent manufacturing plants provide customers with complete sets of technical solutions and excellent products.The company adheres to the enterprise spirit of "integrity, innovation, efficiency and self-discipline", firmly follows the enterprise development path of "specialization, specialization and innovation", and contributes its wisdom and products to the society. Sincere thanks to our customers for their many years of support and love!