Material Characteristics of PEEK Wearable Sealing Material

Industrial sealing raw materials PEEK, in black powder form, represent PEEK material that is revolutionizing industries.

Injection - Molded Process

The injection - molding of PEEK black powder, which is a form ofIndustrial sealing raw materials PEEK, creates precise, complex - shaped seals. This process evenly distributes the PEEK material, ensuring consistent product quality. The unique properties of PEEK material enable it to be effectively processed through injection - molding, resulting in seals with excellent dimensional accuracy.

Strong Mechanical & Low - Friction Features

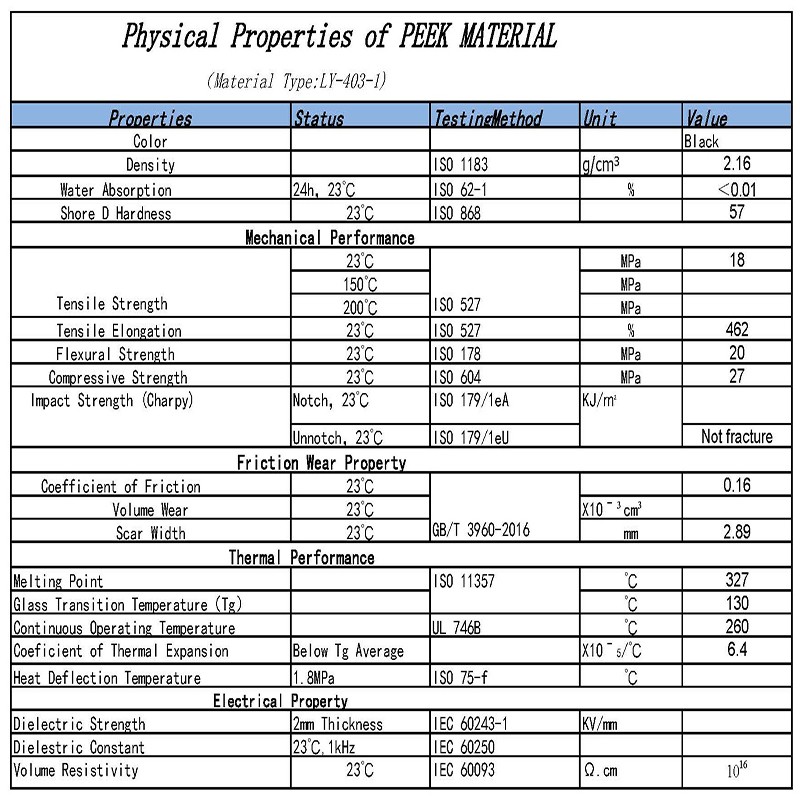

PEEK abradable seals, made from PEEK material, have high tensile strength, withstanding stress in high - pressure setups. The inherent strength of PEEK material allows these seals to maintain their integrity under extreme mechanical loads. Their low - friction coefficients, a characteristic of Industrial sealing raw materials PEEK, reduce wear on both the seal and mating surfaces, extending seal life and system efficiency. In rotating machinery, PEEK material - based seals cut energy use by minimizing resistance, thanks to the material's low - friction nature.

Matched Expansion with Aluminum

PEEK seals, composed of PEEK material, have a linear expansion coefficient similar to aluminum's. When paired with aluminum parts, the PEEK material in the seals expands and contracts together as temperature changes, preventing gaps and maintaining a tight seal. This compatibility of PEEK material with aluminum is crucial in applications like car engines and aerospace components with temperature swings. The ability of PEEK material to adapt to temperature - induced dimensional changes makes it an ideal choice for such demanding scenarios.

Stable & Abrasion - Resistant for Precision Sealing

PEEK abradable seals, crafted from PEEK material, stay stable and keep sealing well, even in harsh conditions. The stability of PEEK material allows these seals to maintain their shape and function over time. Their high abrasion resistance, a key property of PEEK material, allows them to function in environments with particulate matter or high - speed fluids. This makes PEEK material - based seals perfect for high - precision sealing in medical syringe pumps and semiconductor manufacturing, where reliability and precision are of utmost importance.