Introduction to PEEK Solenoid Valve Parts

The PEEK solenoid valve parts, specifically the PEEK signal components, are integral elements within the PEEK connector electrical system. These components, often including the PEEK Connector clip, are crafted from polyether ether ketone (PEEK), a high - performance material. The PEEK Connector clip, as part of the PEEK solenoid valve parts, and the PEEK connector electrical as a whole, have revolutionized the landscape of valve technology, especially in systems demanding rapid and accurate fluid control.

Material - Driven Advantages

PEEK's chemical stability is a cornerstone of its performance. The PEEK signal components, which are connected using the PEEK Connector clip within the PEEK insulated connector setup, can resist the corrosive effects of a vast array of chemicals. In the chemical industry, where highly reactive substances are routinely handled, these components, firmly held together by the PEEK Connector clip in the PEEK connector electrical system, can withstand exposure to strong acids, alkalis, and organic solvents without degradation. This resistance ensures that the solenoid valve parts, as part of the PEEK connector electrical, maintain their structural integrity and functionality over extended periods, even in the harshest chemical environments. For instance, in a chemical plant producing specialty chemicals, the PEEK signal components in the solenoid valves, with the PEEK Connector clip ensuring a secure connection within the PEEK connector electrical, can operate flawlessly while in contact with aggressive reaction intermediates.

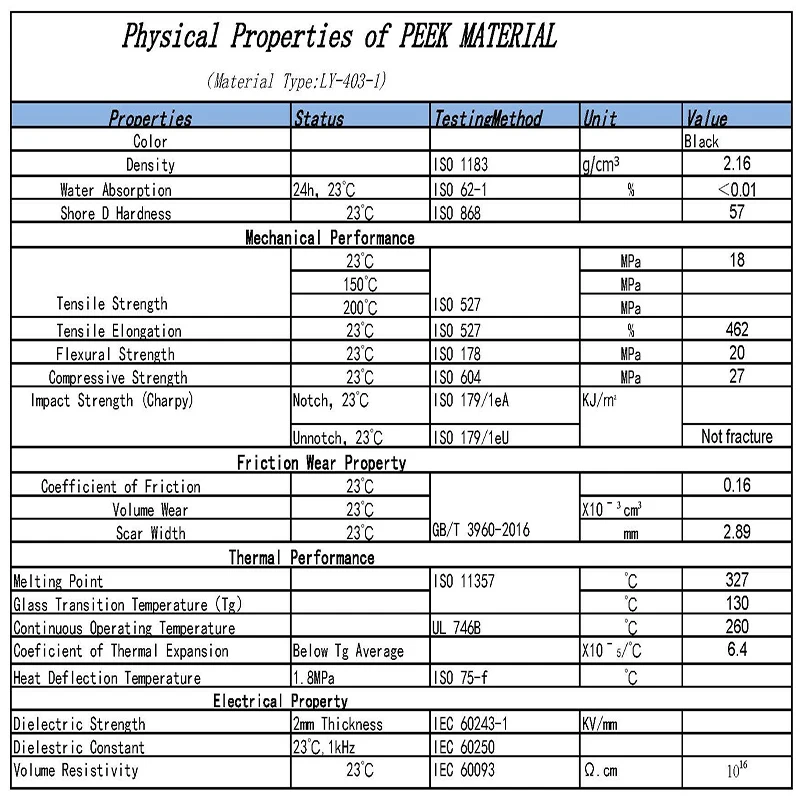

PEEK has an impressive ability to endure high temperatures. PEEK solenoid valve parts, which are integral to the PEEK connector electrical, can function effectively in elevated - temperature conditions, often up to 260°C or more in some specialized applications. This property makes them ideal for use in industries such as petroleum refining, where processes involve high - temperature fluids. In a refinery's distillation unit, the PEEK - based signal components in solenoid valves, with the PEEK Connector clip maintaining a stable connection within the PEEK connector electrical, can accurately control the flow of hot hydrocarbons, ensuring smooth and efficient separation of different fractions.

Despite its relatively lightweight nature, PEEK offers high mechanical strength. The PEEK signal components, held in place by the PEEK Connector clip in the PEEK connector electrical, can withstand the mechanical stresses associated with the rapid opening and closing actions of solenoid valves. In applications where valves are cycled frequently, such as in automated pharmaceutical manufacturing processes, the PEEK parts, as part of the PEEK connector electrical with the PEEK Connector clip ensuring their connection, can endure repeated mechanical impacts without significant wear. This durability reduces the need for frequent replacements of the PEEK connector electrical components, leading to lower maintenance costs and increased system uptime.

The PEEK insulated connector has good dimensional stability and can work closely with supporting components to ensure the reliability of the connection.

PEEK insulated connector can still maintain good performance in high temperature environments and adapt to a variety of complex working conditions. .

PEEK insulated connector has good insulation properties and effectively ensures the safety and reliability of current transmission.

We the company has always stood at the forefront of technological innovation, At the same time, the company actively participates in the formulation of industry standards to ensure product quality and the healthy development of the industry. specialization, specialization and new.

The company has a series of independent intellectual property rights, including a number of invention and utility model patents. These achievements not only fill the gaps in my country's technology and products in this field, but also help the company become a leading enterprise in this field . On this basis, the company continues to increase investment in research and development and is committed to providing customers with more advanced and complete technical solutions.