Introduction to PEEK Fiberglass Sheet

PEEK fiberglass sheet is a high - performance composite. It combines polyetheretherketone (PEEK) resin with glass fiber and other additives.

Manufacturing Process

To make PEEK fiberglass sheets, high - purity PEEK resin is melted first. Then, glass fibers (continuous or short) are mixed into the molten resin. The mixture is processed using extrusion or compression molding. In extrusion, it's pushed through a die to form sheets. Compression molding involves placing the mixture in a mold, applying heat and pressure to shape it.

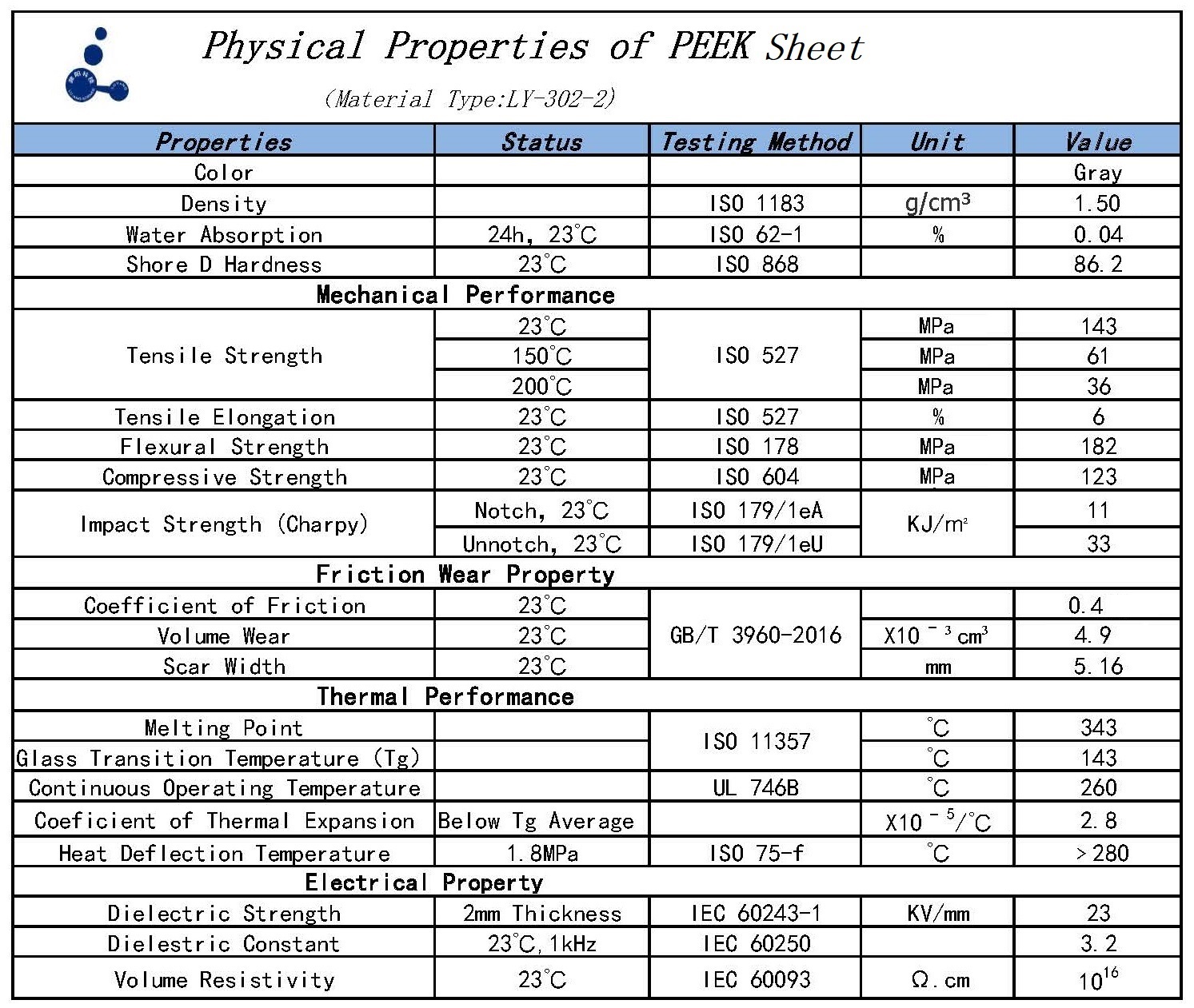

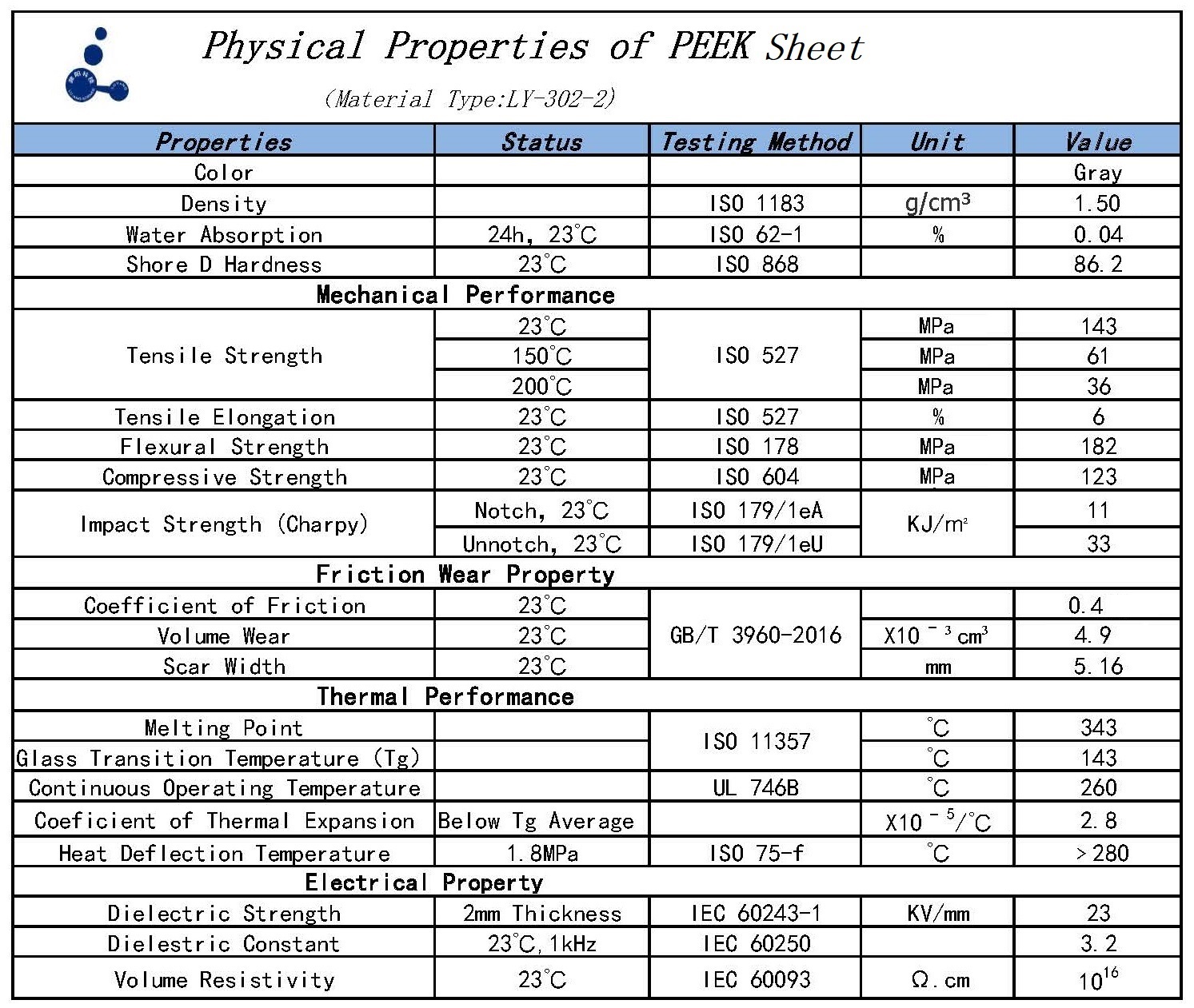

Properties

PEEK is a thermoplastic with great chemical resistance, mechanical strength, fatigue resistance, and dimensional stability across a wide temperature range. Glass fiber, as a reinforcement, boosts the composite's mechanical properties. Together, they create a lightweight yet strong material compared to traditional metals.

Performance Advantages

Lightweight and Strong

PEEK fiberglass sheets are much lighter than metal sheets of similar strength. In aerospace, this helps cut weight and improve fuel efficiency, while still withstanding mechanical loads for structural parts.

High - Temperature Resistant

The composite can keep its properties at high temperatures. It can be used continuously at up to 250°C in some cases, fitting for high - heat environments like automotive engines.

Chemically Resistant

The composite retains PEEK's chemical resistance. It's suitable for chemical plants, resisting corrosion from various chemicals for long - term use.

Common Applications

Aerospace

Used for aircraft interior components like cabin panels and structural parts like wing ribs, reducing aircraft weight.

Automotive

Applied to engine - compartment parts such as radiator end tanks and engine covers, enduring harsh under - hood conditions.

Electronics

Used as printed circuit board (PCB) substrates due to dimensional stability and electrical insulation, ensuring device reliability.

In summary, PEEK fiberglass sheets are versatile and valuable in high - tech industries.

Advantages of PEEK fiberglass sheet:

1. PEEK glass fiber reinforced sheet provides excellent tensile strength and rigidity, making it ideal for applications that bear heavy loads and sustained stress.

2. PEEK glass filled sheet has excellent wear resistance and can resist wear in various environments and extend its service life.

3. PEEK glass filled sheet has excellent chemical resistance and weather resistance, reducing the need for repairs and replacements and reducing long-term operating costs.

Details of PEEK fiberglass sheet:

Applications of PEEK GF glass filled sheet:

PEEK GF glass filled sheet is often used in the automotive industry, aerospace, petroleum and chemical industry, electronic and electrical, sports equipment, medical equipment, construction industry and other fields.

Why choose us?

We have many years of experience in the production and application of PEEK Glass Filled sheet and can provide customers with professional technical support and solutions.

We provide customized PEEK Glass Filled sheet services and can customize and produce PEEK Glass Filled sheets according to customers' specific needs to meet different application requirements.

We provide comprehensive after-sales services, including technical consultation, PEEK Glass Filled sheet repair and replacement, etc., to ensure that customers' long-term use needs are met.