On October 15, 2024, the sky in Dalian was crystal - clear, and the gentle autumn breeze carried a refreshing coolness, creating an ideal setting for an enriching academic - industrial exchange. At the "production, study, and research" base within Dalian Luyang Technology's state - of - the - art production and development building, a significant event was unfolding. This base, in close collaboration with Dalian Polytechnic University, serves as a crucial platform for knowledge transfer and innovation, especially in the realm of PEEK products and PEEK material.

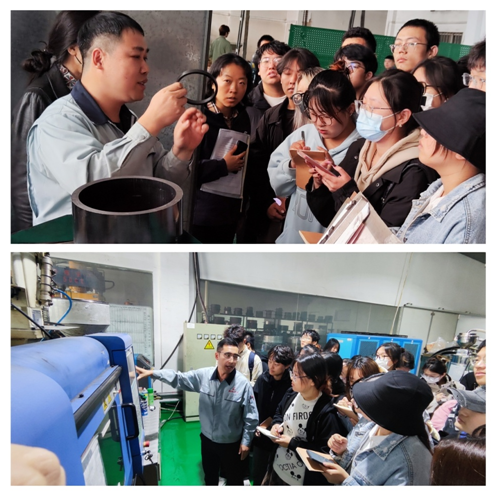

The graduate class from the School of Polymer Materials of Dalian Polytechnic University, led by the esteemed Professor Qu, arrived with great enthusiasm. These students, eager to expand their knowledge in the field of polymer materials, were particularly interested in the advanced technologies related to PEEK products and PEEK material. They formed an attentive audience, their eyes fixed on the speakers as they prepared to delve deep into the world of special engineering plastics. Each student was well - aware of the growing significance of PEEK products and PEEK material in modern industries and was eager to learn more.

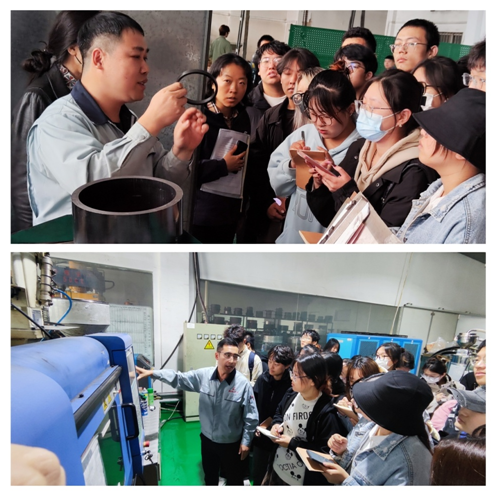

Engineers from Luyang Technology's Materials R & D Department and Technical Process Department took the stage. The R & D engineers first introduced the fundamental properties of PEEK material. They explained how the unique molecular structure of PEEK material, with its specific arrangement of chemical bonds, contributes to its exceptional high - temperature resistance, chemical corrosion resistance, and outstanding mechanical properties. For instance, PEEK material can withstand extremely high temperatures, remaining stable even in environments where the temperature soars to several hundred degrees Celsius. This makes it an ideal choice for high - performance PEEK products used in aerospace engine components, such as PEEK - based turbine blades and PEEK - reinforced seals. In the aerospace industry, the reliability of PEEK products made from high - quality PEEK material is of utmost importance.

Picture 1: Students of the graduate class visit the practice base

Dalian Luyang Technology has been insisting on deepening the construction of "industry-university-research" base with Jilin University, Dalian University of Technology, Dalian University of Technology, and Beijing Institute of Petrochemical Technology in the past two decades. We have jointly developed a batch of high-quality PEEK composite materials with high gold content, and trained a batch of polymer materials professionals. Luyang people have been working hard to contribute their wisdom and strength to the society.

Figure 2: Luyang Technology R & D and molding engineers explain at the scene.