Luyang Technology's PEEK raw material, which serves as the foundation for crafting remarkable PEEK material, represents a truly special polymer material. It is highly esteemed for its wide - ranging and outstanding properties.

Unique Molecular Structure and Its Implications

The main chain structure of the PEEK material, derived from the PEEK raw material, is distinctively designed. It features a repeating unit consisting of one ketone bond and two ether bonds. This particular molecular arrangement bestows upon the PEEK material the characteristics typical of semi - crystalline polymer materials. The semi - crystalline nature of the PEEK material, stemming from the unique composition of the PEEK raw material, plays a pivotal role in determining its overall performance. It contributes significantly to the PEEK material's balance of rigidity and toughness, which is crucial for its diverse applications.

Exceptional High - Temperature Resistance

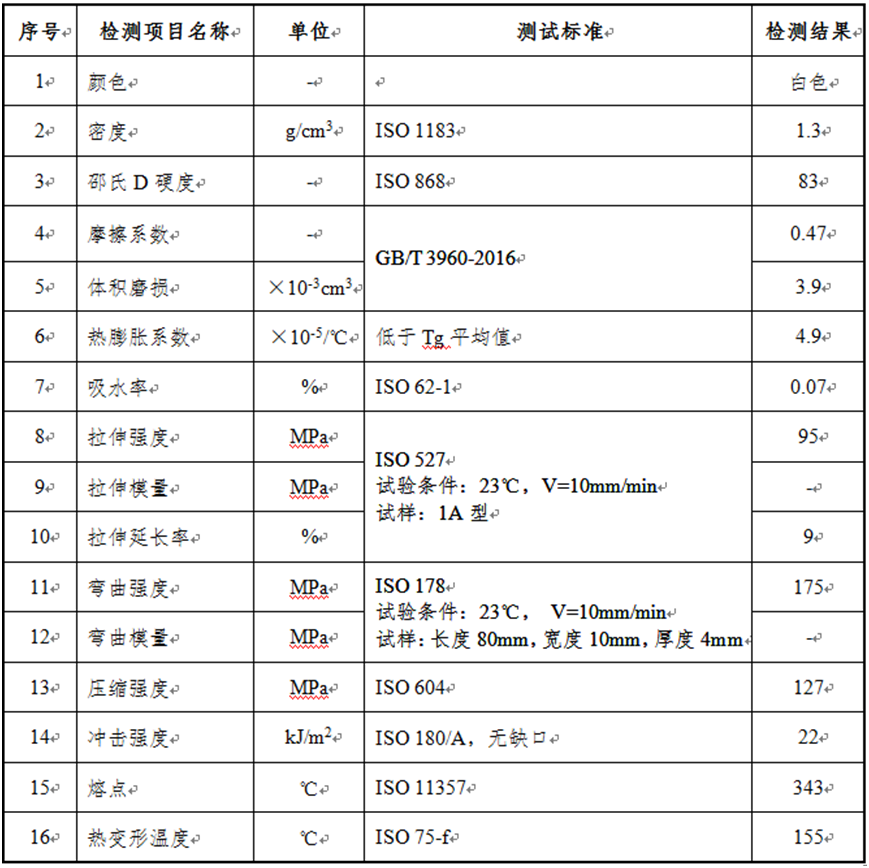

PEEK material, processed from the PEEK raw material, showcases remarkable high - temperature resistance. It can effortlessly endure elevated temperatures, steadfastly maintaining its structural integrity and mechanical properties. With a high glass transition temperature, often exceeding 143°C, and a melting point around 343°C, the PEEK material, sourced from the PEEK raw material, remains stable even in the most extreme heat conditions. This property renders the PEEK material an ideal choice for applications in high - temperature environments. For instance, in aerospace engine components or industrial furnaces, the PEEK material, crafted from the PEEK raw material, can ensure reliable operation.

Superb Chemical Corrosion Resistance

The chemical corrosion resistance of the PEEK material, produced from the PEEK raw material, is equally impressive. It can bravely withstand exposure to a vast array of corrosive chemicals, including strong acids like sulfuric acid and aggressive alkalis such as sodium hydroxide. In chemical processing plants, where pipelines and reaction vessels are constantly subjected to harsh chemical environments, PEEK - based components made from the PEEK raw material can substantially extend the service life of equipment. The PEEK material's resistance to chemical attack, attributed to the quality of the PEEK raw material, ensures reliable performance even in the most demanding chemical applications.

Outstanding Mechanical Properties

High Strength and Rigidity

PEEK material, derived from the PEEK raw material, boasts high strength and rigidity. In its composite form, it frequently demonstrates a tensile strength reaching up to 1,800 MPa or more, combined with a high modulus of elasticity, typically within the range of 120 - 180 GPa. This empowers the PEEK material to bear substantial mechanical loads. In high - performance sports equipment like tennis rackets and bicycle frames, the PEEK material's strength - to - weight ratio, stemming from the properties of the PEEK raw material, provides excellent shock absorption and structural stability, thereby enhancing the performance of these products.

Good Self - Lubrication

The self - lubricating property of the PEEK material, originating from the PEEK raw material, is due to its low coefficient of friction, usually within the range of 0.1 - 0.3. This property effectively reduces friction between moving components, minimizing wear and tear. In automotive engines, PEEK - made piston rings crafted from the PEEK raw material can operate smoothly, leading to reduced energy consumption and an extended engine lifespan. The PEEK material, processed from the PEEK raw material, also finds applications in conveyor systems, where smooth component movement is essential for efficient operation.

Additional Superior Features

Flame Retardant

PEEK material, produced using the PEEK raw material, is inherently flame - retardant, with a limiting oxygen index (LOI) of around 35 - 38. This implies that it requires a relatively high oxygen concentration to support combustion. In applications where fire safety is of utmost importance, such as in aircraft interiors, the PEEK material, derived from the PEEK raw material, can prevent the rapid spread of flames, providing valuable time for evacuation.

Peel Resistance

Engineered to withstand significant stress, the PEEK material, made from the PEEK raw material, has excellent peel resistance. Its molecular structure and the strong bond between its components, both influenced by the PEEK raw material, ensure that it does not easily peel or flake off under mechanical stress. This property is vital in applications such as the manufacturing of protective coatings on industrial machinery, where the long - term integrity of the PEEK material, based on the quality of the PEEK raw material, is crucial.

Radiation Resistance

The PEEK material's ability to resist radiation, stemming from the characteristics of the PEEK raw material, makes it suitable for use in environments with radiation exposure. In nuclear power plants, components made of PEEK material, processed from the PEEK raw material, can withstand the ionizing radiation present during reactor operation. In space exploration, the PEEK material, crafted from the PEEK raw material, can be used in the construction of satellite components, ensuring their proper functioning over extended periods.

Stable Insulation

With stable electrical insulation properties, the PEEK material, derived from the PEEK raw material, has a volume resistivity of approximately 10¹⁶ - 10¹⁷ Ω·cm. This makes the PEEK material an excellent choice for insulating electrical components. In high - voltage electrical systems, PEEK - based insulators made from the PEEK raw material can effectively prevent electrical leakage, ensuring the safe and efficient operation of the system.

Hydrolysis Resistance

The PEEK material, produced from the PEEK raw material, can maintain its performance in humid or water - exposed conditions. Even when continuously immersed in water or exposed to high - humidity environments, it does not experience significant degradation in mechanical properties. This makes the PEEK material suitable for applications in marine environments, such as the production of underwater sensors and connectors.

Easy Processing

Another advantage of the PEEK material, processed from the PEEK raw material, is its ease of processing. Manufacturers can shape the PEEK material into various forms according to different application requirements. This flexibility in processing the PEEK material, made possible by the nature of the PEEK raw material, allows for the creation of complex - shaped components, further expanding its potential applications across different industries.

In summary, Luyang Technology's PEEK raw material, which gives rise to the high - quality PEEK material, with its unique molecular structure and comprehensive set of excellent properties, serves as a cornerstone for innovation and development in numerous industries. The PEEK raw material and the resulting PEEK material provide reliable and high - performance solutions for a wide range of applications.