On June 11, 2025, the 9th Shanghai International Aerospace Technology and Equipment Exhibition opened. Dalian Luyang Technology Development Co., Ltd. showcased its advanced PEEK (Polyetheretherketone) solutions, offering new ways to solve aviation lightweighting problems.

The aerospace sector is a highly specialized field where every gram of weight reduction can translate into significant improvements in fuel efficiency, performance, and overall operational cost - effectiveness. In this context, material quality plays a pivotal role in determining the performance of aircraft. PEEK, a high - performance engineering thermoplastic polymer, has rapidly gained prominence in recent years. Its exceptional combination of properties sets it apart from traditional materials. PEEK exhibits remarkable high strength, enabling it to withstand the intense mechanical stresses experienced during flight. It can endure high temperatures without deforming or losing its structural integrity, making it suitable for components operating in the hot environments of aircraft engines. The material's corrosion resistance ensures longevity even in the face of harsh atmospheric conditions and exposure to various chemicals. Additionally, its self - lubrication property reduces friction between moving parts, minimizing wear and tear. With a density of approximately 1.3 - 1.45g/cm³, PEEK is significantly lighter than metals such as aluminum and steel. To put this into perspective, aluminum, a commonly used lightweight metal in aerospace, has a density of around 2.7g/cm³. This substantial difference in density makes PEEK an ideal candidate for weight - critical aerospace applications. For instance, when used in the manufacturing of engine seals, PEEK not only cuts down on the weight of the component but also ensures reliable operation under the tough conditions of high temperature and pressure within the engine, reducing the risk of leakage and enhancing overall engine efficiency.

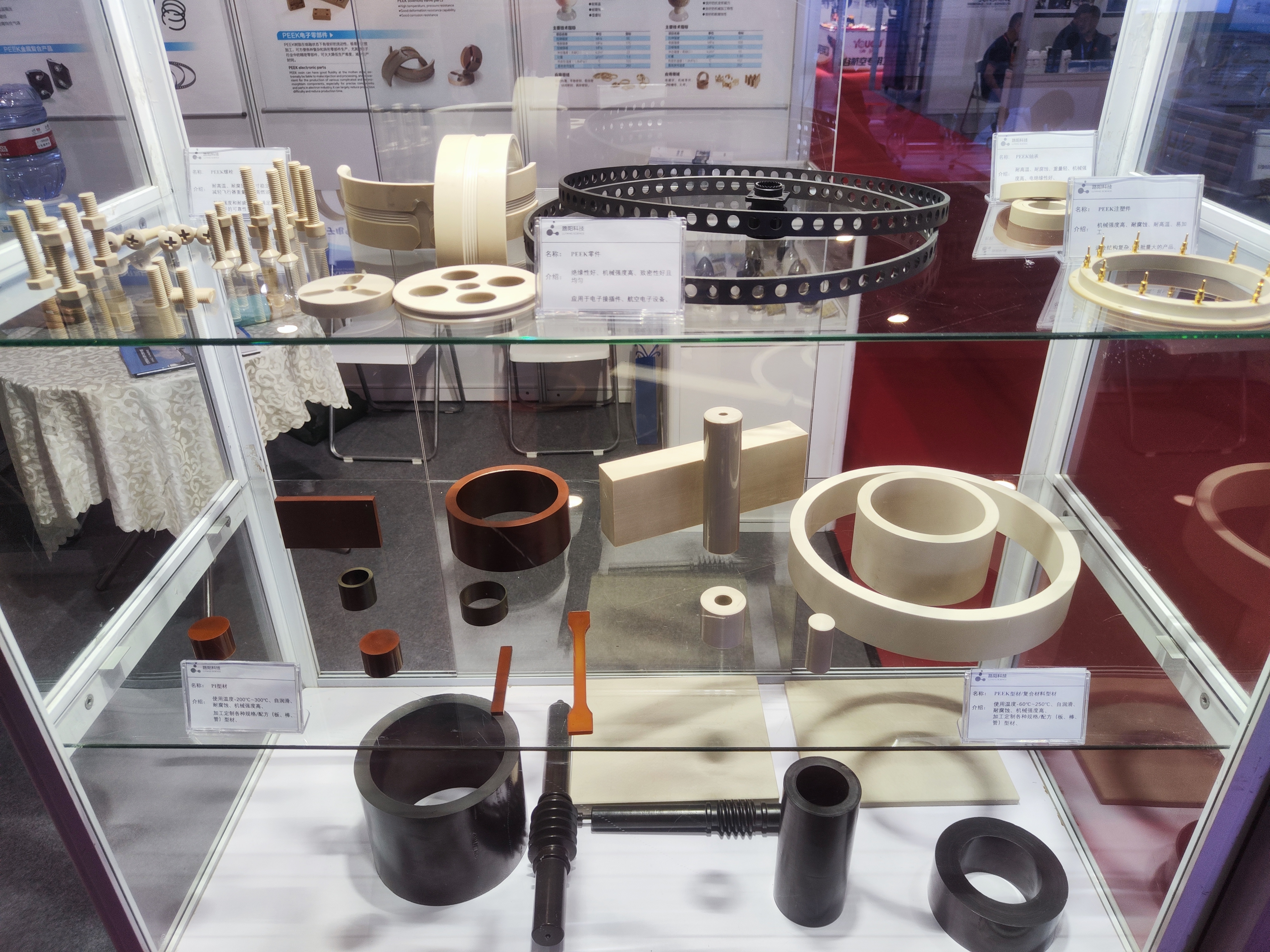

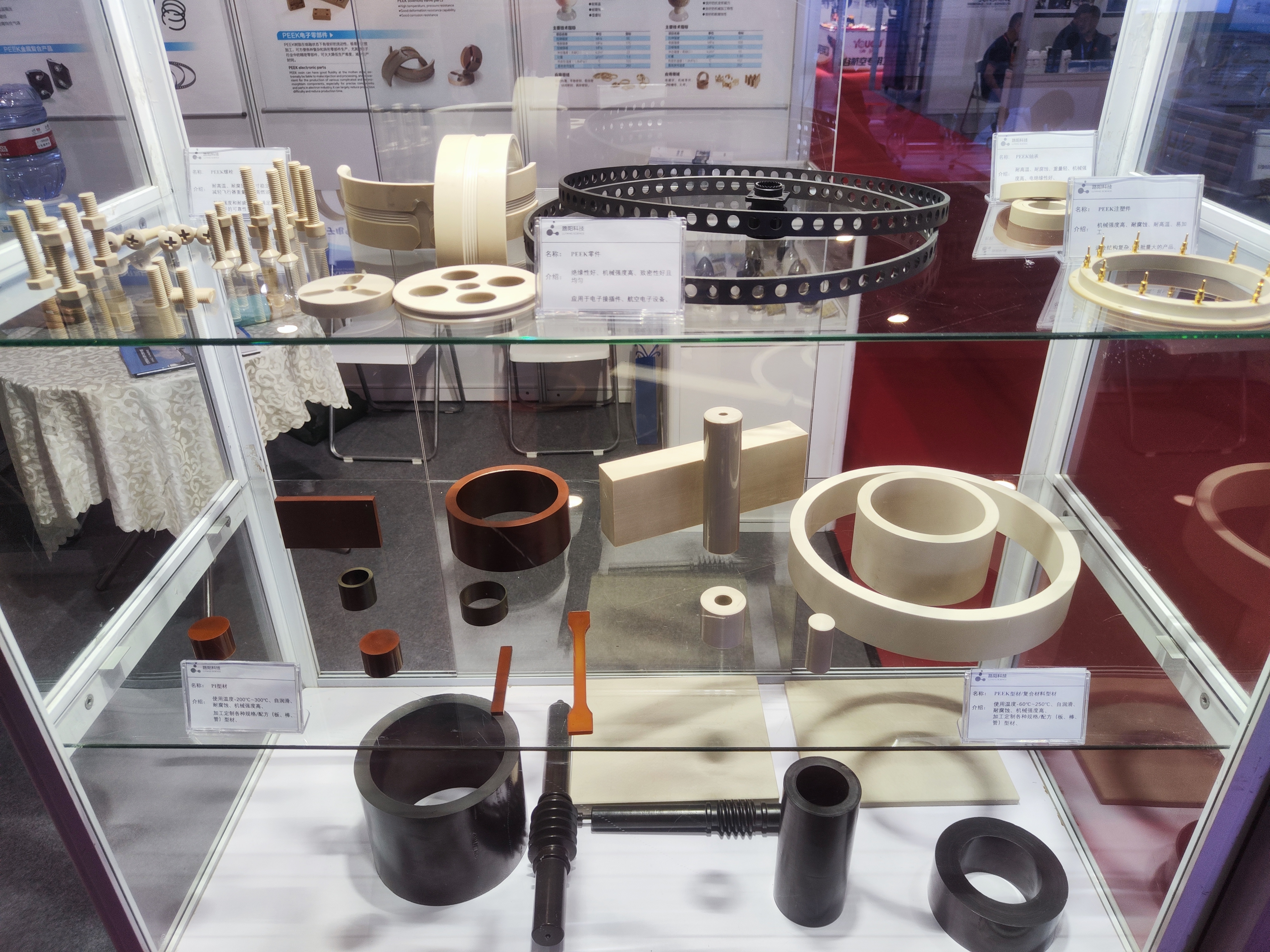

Luyang Technology has long studied PEEK applications. It developed aerospace PEEK components like bearing cages, support seats, bolts, and nuts. A PEEK support seat is 30% - 40% lighter than metal ones, and its self - lubrication reduces maintenance costs. The company also uses PEEK for electronic equipment casings to protect components and reduce weight.

At the exhibition, Luyang’s PEEK products drew experts and representatives. The technical director said the company will keep researching PEEK. New PEEK composites may be used in engine parts, and PEEK stability research in extreme environments has progressed.

Looking ahead, Luyang will invest more in PEEK R&D and cooperate with universities. With its “863” project experience and patents, it leads industry standards. The company plans to break through in PEEK 3D printing for aerospace component production.

The exhibition runs until June 13th. Luyang Technology hopes to partner with more firms to explore PEEK’s potential in aerospace and drive material science forward.