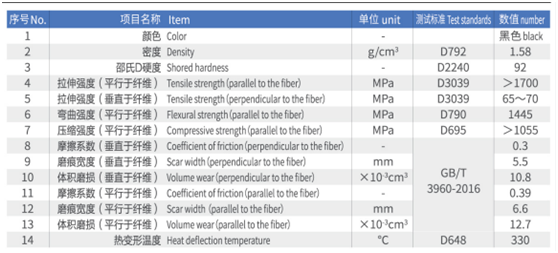

Characteristics of PEEK material

1. Heat resistance: PEEK's ability to maintain performance at extreme temperatures makes it an ideal material for manufacturing high-performance aerospace components.

2. Mechanical strength: PEEK has high tensile strength and fatigue resistance, suitable for repeated use and extreme loads.

3. Chemical resistance: PEEK has good resistance to most solvents, chemicals and radiation, and is suitable for use in harsh environments.

4. Self-lubrication: The self-lubricating performance of PEEK reduces the friction between components and extends the service life of the equipment.

PEEK applications in aerospace

1. Due to the heat resistance of peek polymer material, it is often used in the manufacture of the impeller and blade in the steam turbine engine, as well as the manufacture of high-temperature structural parts in the aircraft engine, and the fuel pipeline and high-temperature pipeline of the space shuttle.

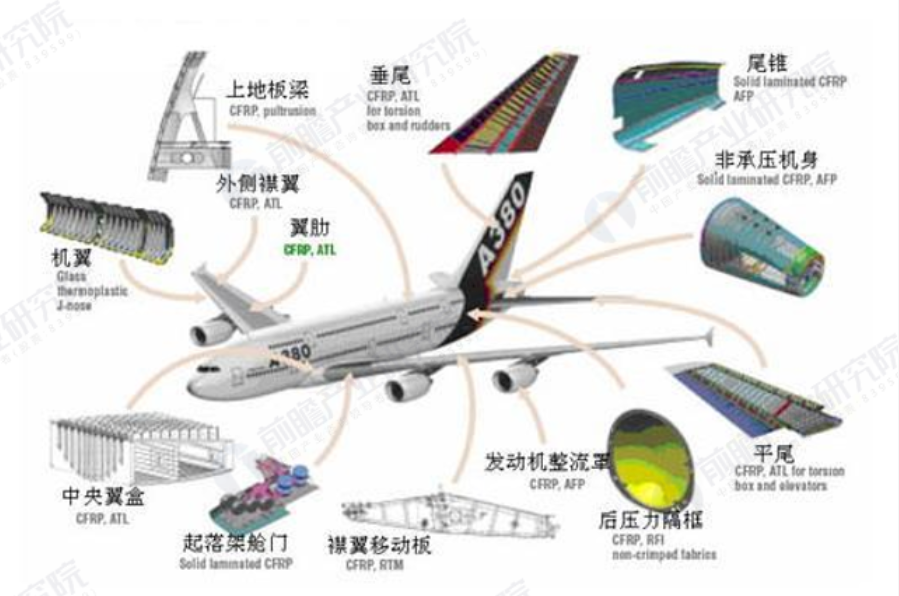

2.PEEK composite material has high mechanical properties, can adapt to complex working environment and high requirements of the use of conditions, so as to ensure the reliability and safety of aircraft. PEEK composite materials can also be used to manufacture aircraft, missiles and satellites and other aircraft structural parts, such as fuselage, tail, hub, gear and drive shaft.

3.PEEK polymer material has good chemical corrosion resistance and plastic formability, and is widely used in aircraft flaps, ribs and frames.

4. PEEK composite material also has the characteristics of self-lubrication to manufacture multi-specification bearing retainers, gaskets, standard parts and camera reflection frames, etc., to achieve double effects of weight reduction and oil-free lubrication.

In addition, Airbus A350 to A900 aircraft door fittings use a high-modulus carbon fiber reinforced PEEK material. Using this material, it is easy to drill, and can achieve 40% weight reduction and 40% cost savings. PEEK piping is now specified for use in the cargo hold drainage system of the Airbus A350XWB. In the field of aerospace, glass fiber reinforced PEEK materials have been successfully applied to satellite lithium battery parts, high temperature insulation rings and so on.

Dalian Luyang Technology Co., Ltd. after years of research, continuous optimization of the process, has been put into the market of aerospace PEEK products are fuel filter, support base, bolts, nuts and coil, bearing cage and other parts, rocket battery tank and rocket engine parts. With the efforts of Lu Yang people, more and more products will be applied to the field of aerospace in the future.

http://www.luyangkeji.com

http://www.peek-luyang.com