Efficient Rotation in Diverse Environments: At the heart of its function, the Polyimide Wheel, including the Diamond Polymide Wheel and Polymid Bond Wheels, is designed to enable smooth and efficient rotation. In high - speed conveyor systems within the electronics industry, for example, these wheels must rotate rapidly while maintaining stability. The polyimide construction, characteristic of the Diamond Polymide Wheel and Polymid Bond Wheels, ensures that they can handle the high rotational speeds without succumbing to excessive wear or deformation. They provide a reliable rolling motion, facilitating the movement of products along production lines with precision.

Load - Bearing Capability: One of the key functions of the Polyimide Wheel, such as the Diamond Polymide Wheel and Polymid Bond Wheels, is their remarkable load - bearing capacity. In precision machinery applications, where heavy loads need to be transported or supported during manufacturing processes, these wheels can withstand substantial weights. Whether it's in a high - tech manufacturing facility producing aerospace components or in a precision optics manufacturing plant, the Diamond Polymide Wheel and Polymid Bond Wheels can carry the load, ensuring that the machinery operates smoothly and without disruption.

Advantages of Polymide Wheel:

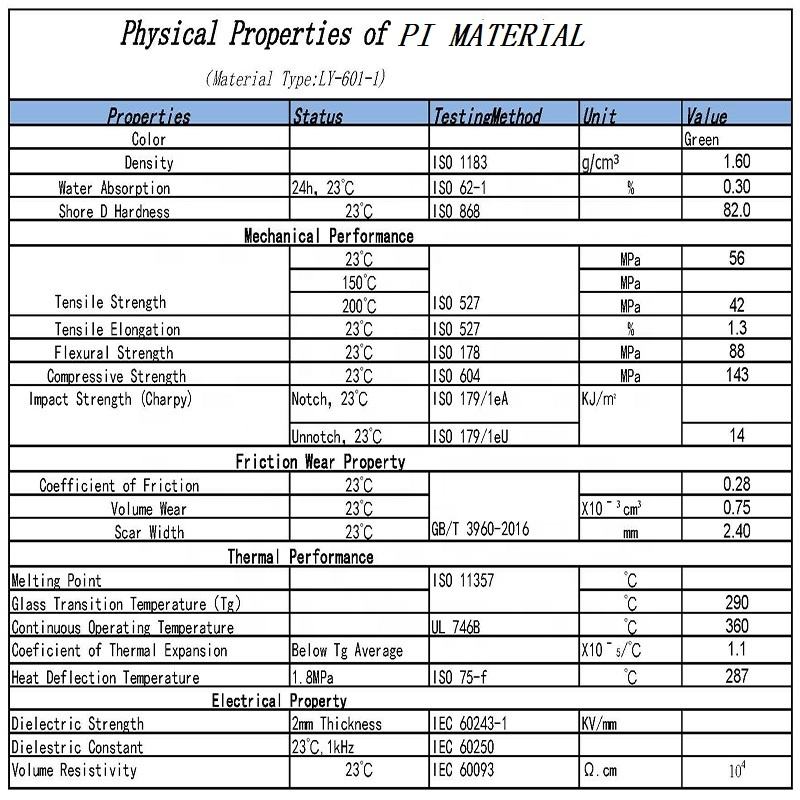

1. The thermal stability of Polymide Wheel is extremely high, and it can maintain performance in the temperature range of -200 ℃ to+300 ℃, far exceeding that of ordinary roller materials.

2. Polymid Bond Wheels have a low coefficient of friction, smooth operation, and can reduce equipment wear and energy consumption.

3. Polymid Bond Wheels can withstand higher loads to ensure stable operation of the equipment.

4. Under normal operating conditions, the service life of Polymid Bond Wheels can reach tens of thousands of hours, reducing the frequency of replacement and maintenance costs.

Details of Diamond Polymide Wheel:

Application of Diamond Polymide Wheel:

Diamond Polymide Wheel is widely used in various applications that require high precision, wear resistance, and high temperature resistance due to its excellent performance, such as aerospace, electronic manufacturing, printing industry, laboratory equipment, and medical equipment.

Why did you choose us?

We continue to invest in research and development, continuously optimizing the design and manufacturing process of Diamond Polymide Wheel to meet the growing needs of our customers.

Years of industry experience and good reputation have earned us the trust and recognition of our customers. Choosing us means choosing quality and reputation.