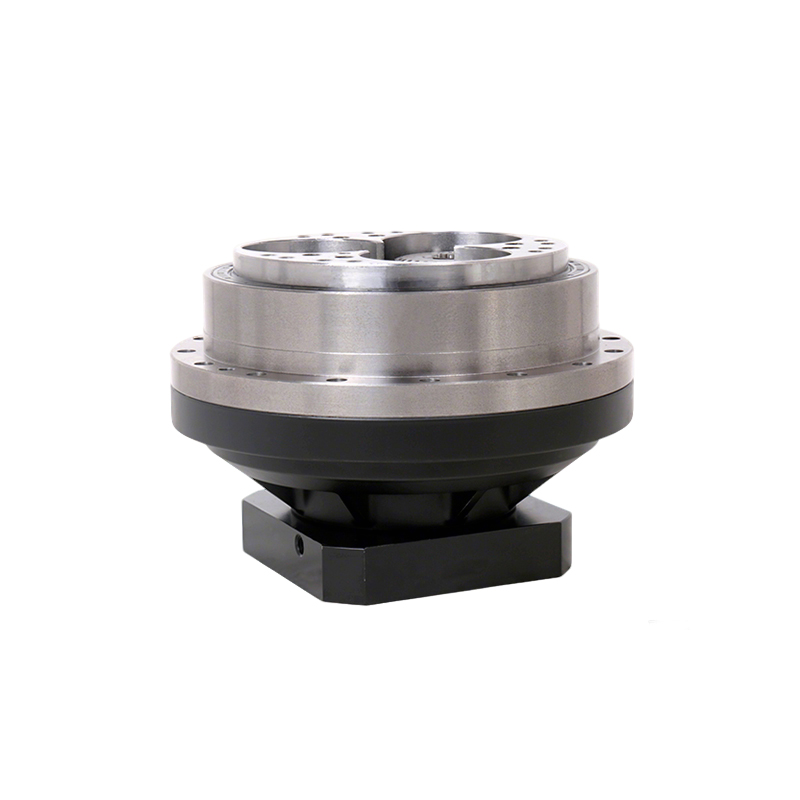

The PEEK robot RV reducer is a high-precision reduction device that applies PEEK (Polyether Ether Ketone) composite materials to the RV (Rotary Vector) transmission structure, integrating the high rigidity of RV reducers with the lightweight advantage of PEEK materials. The following is an introduction from the aspects of structural innovation, material properties, performance indicators, and application scenarios:

I. Structural Innovation

It adopts a two-stage reduction structure: the first stage is planetary gear reduction (sun gear + 3 planetary gears), and the second stage is cycloidal pinwheel reduction (2 cycloidal wheels with a phase difference of 180°). In the core transmission components, the cycloidal wheels are made of 30% carbon fiber reinforced PEEK injection molding, the pin teeth pins are PEEK-metal composite structures (PEEK wear-resistant layer on the outside + steel core shaft), and the eccentric shaft bearing housing integrates PEEK self-lubricating bushings, enabling long-term operation without oil. The overall structure is optimized through finite element topology, reducing the number of parts by 25% compared to traditional steel RV reducers.

II. Material Properties

Strength-to-weight ratio advantage: The tensile strength of the PEEK cycloidal wheel reaches 180MPa, with a density of only 1.45g/cm³, reducing the weight by 55% compared to steel cycloidal wheels. At the same time, the tooth root bending strength is increased by 40% through carbon fiber orientation design.

Dynamic performance: The material damping coefficient is 0.02 (0.001 for steel), reducing transmission noise by 15-20dB and increasing the resonance frequency to over 3000Hz.

Environmental adaptability: It maintains stable mechanical properties within the temperature range of -60°C to 220°C, is resistant to hydraulic oil and gear oil erosion, and meets the IP67 protection level requirements.

III. Core Performance Indicators

Transmission accuracy: Backlash ≤ 15 arc seconds, repeat positioning accuracy ±5 arc seconds, no-load start torque fluctuation ≤ 3%.

Load capacity: Rated output torque 80-300N・m (corresponding models RV-40 to RV-110), short-term overload factor 2.5 times.

Efficiency and lifespan: Transmission efficiency 94%-96% (at 2000rpm input), MTBF (Mean Time Between Failures) > 20,000 hours (under rated conditions).

IV. Typical Application Scenarios

Humanoid robots: Large-load parts such as waist rotation joints and knee joints, such as the hip joint drive unit of Tesla Optimus (requiring 200N・m class reducers).

Industrial robots: J2/J3 axes of six-axis mechanical arms, replacing traditional harmonic reducers to achieve higher rigidity.

High-end equipment: Semiconductor wafer handling robots, surgical robot end effectors, which need to simultaneously meet lightweight and micron-level positioning accuracy requirements.