Product Background

With the development of the hydrogen energy industry, alkaline electrolyzers have become the mainstream route for hydrogen production through water electrolysis due to their advantages such as simple structure, high technological maturity, safety and stability, as well as relatively low cost. The performance improvement of core components such as electrodes, plates, frames, separators, and sealing gaskets is crucial for the technological upgrade and iteration of alkaline electrolyzers and for solving the problem of green electricity hydrogen production. It is against this backdrop that the hydrogen energy inserts of Luyang Technology were born.

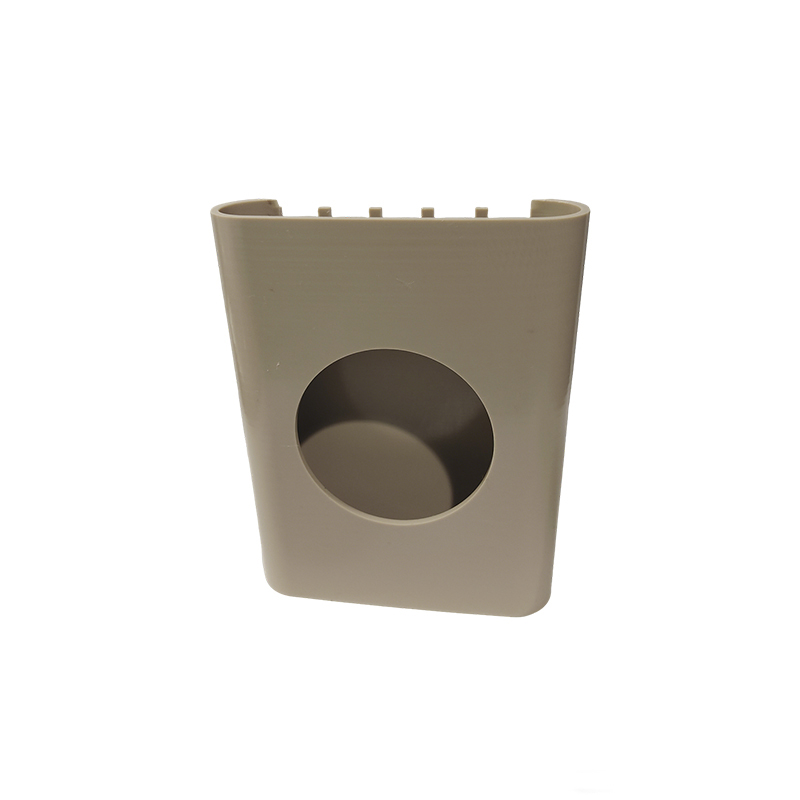

Product Features

Material advantages: As a professional manufacturer specializing in modified materials and products of special engineering plastics such as PEEK and PI, Luyang Technology mainly uses plastics like PTFE (polytetrafluoroethylene) and PSU (polysulfone) for its hydrogen energy inserts. These plastics have high resistivity and can effectively reduce the occurrence of parasitic electrolysis, thereby enhancing the purity of the gas. It also has good corrosion resistance and is not easily eroded by electrolytes, which can extend the service life of the electrolytic cell.

Lightweight design: Plastic electrode frames are lighter than traditional metal electrode frames, which helps to reduce the overall weight of the electrolytic cell and lower transportation and installation costs.

Good processing and formability: Plastic materials have excellent processing performance and can be fabricated into complex structures through injection molding and other processes to meet the diverse design requirements of electrolytic cells.

Application scenarios

Alkaline electrolytic cell: Mainly applied in alkaline electrolytic cells, it serves as a part of the electrode plate and is welded to the main electrode plate to form the electrode plate structure. It plays a role in conducting electrons and blocking the alkali solutions at the cathode and anode, and is a key component in the entire process of hydrogen production through water electrolysis.

Market competitive advantage

Technical research and development strength: Luyang Technology has a professional R&D team and has accumulated profound technical experience in the field of modified materials and products of special engineering plastics. It can provide customers with complete technical solutions, which makes its hydrogen energy inserts competitive in terms of performance and quality.

Product diversification: The company can, based on the diverse needs of different customers, leverage its material processing advantages to produce hydrogen energy inserts of various specifications and structures, to meet the requirements of different types of electrolyzers and better adapt to the diverse demands of the market.