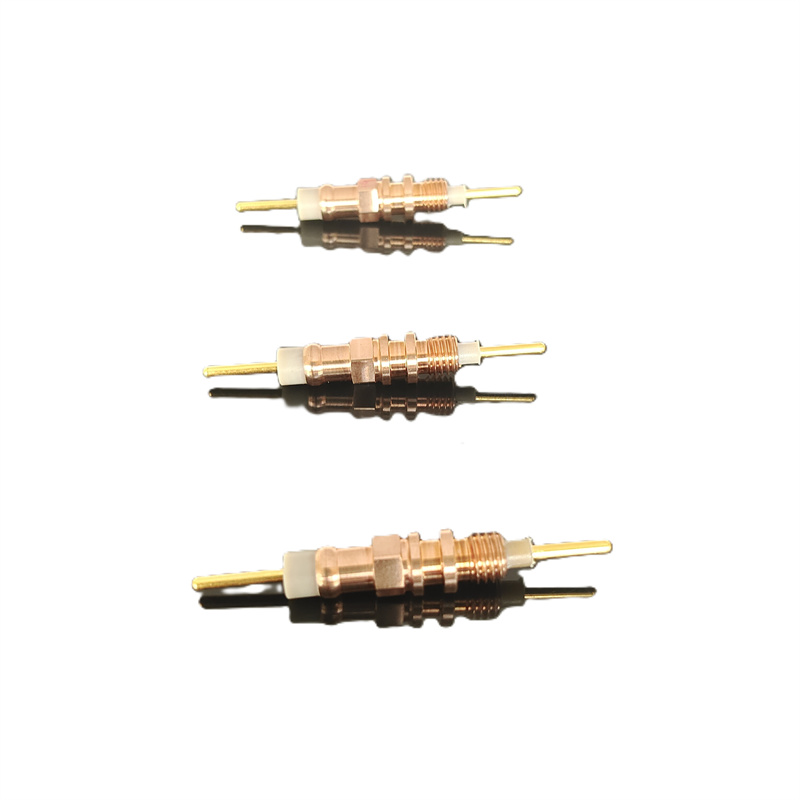

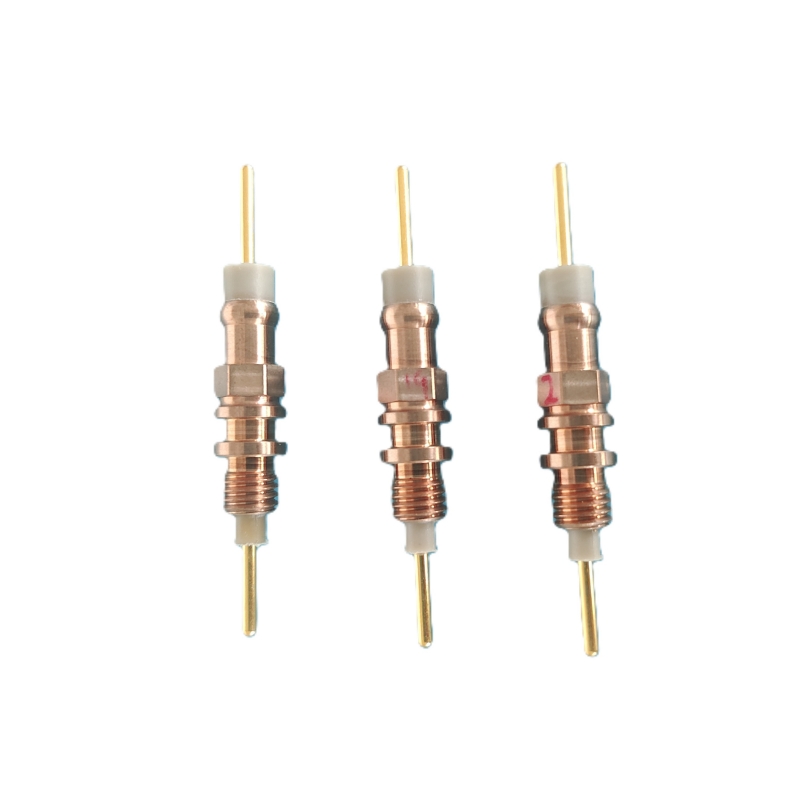

PEEK Electronic pin product introduction:

PEEK Electronic pin is a common connection element, usually a slender metal needle structure.

The main function of electronic pin is to achieve electrical connection, signal transmission or mechanical fixation between components in the fields of electronics, electrical and mechanical.

We use PEEK material to produce electronic pin. Peek material has good sealing performance and small thermal expansion coefficient. As the temperature changes, the size of peek electronic pin changes little.

Advantages of PEEK Electronic pin:

PEEK Electronic pin has good electrical insulation performance, which can effectively prevent current leakage and short circuit, and ensure the accuracy and stability of signal transmission.

Compared with traditional metal pins, PEEK pins are lighter, which helps to reduce the weight of the entire device.

PEEK Electronic pin has strong self-lubrication and low friction coefficient during plugging and unplugging, which reduces wear and extends service life.

PEEK Electronic pin is resistant to high temperature and high pressure, and has a high glass transition temperature (Tg=143℃) and melting point (Tm=343℃).

Application areas of PEEK Electronic pin:

In electronic devices, PEEK Electronic pin can establish circuit connection by inserting into the corresponding jack to achieve communication and power transmission between different electronic components.

In the electrical field, like the PEEK Electronic pin in the plug and socket, it is used to connect electrical equipment to power or other equipment.

Why choose PEEK material pin over traditional Electronic pin ?

1. Compared with traditional pin materials, PEEK material pin can work stably at 260℃ or even higher. Traditional pins may soften or deform due to high temperature, affecting signal transmission.

2. Many traditional pins are easily corroded by chemicals, and PEEK material pin can maintain good performance for a long time.

3. Compared with traditional pins made of metal materials, PEEK material pin is lighter. Using PEEK material pin can reduce the weight of the equipment without affecting performance.

4. In high-precision electronic instruments, PEEK material pin can reduce electromagnetic interference and ensure accurate measurement of the instrument.

About US:

The company is a professional manufacturer of PEEK, PI and other special engineering plastic modified materials and products. It is the R&D and production base for PEEK and other special engineering modified plastics and modified material products, as well as additive manufacturing in China. Its products are widely used in electronics, aerospace, military industry, petrochemical industry, automobiles, mechanical equipment, various seals and other fields.