Introduction to PEEK Electromagnetism Valve Parts

PEEK electromagnetism valve parts, part of PEEK electrical parts, are made from high - performance PEEK thermoplastic. PEEK is prized for its strong mechanical strength, great chemical stability, and good electrical insulation. PEEK modified solenoid valve parts are especially popular in industrial uses.

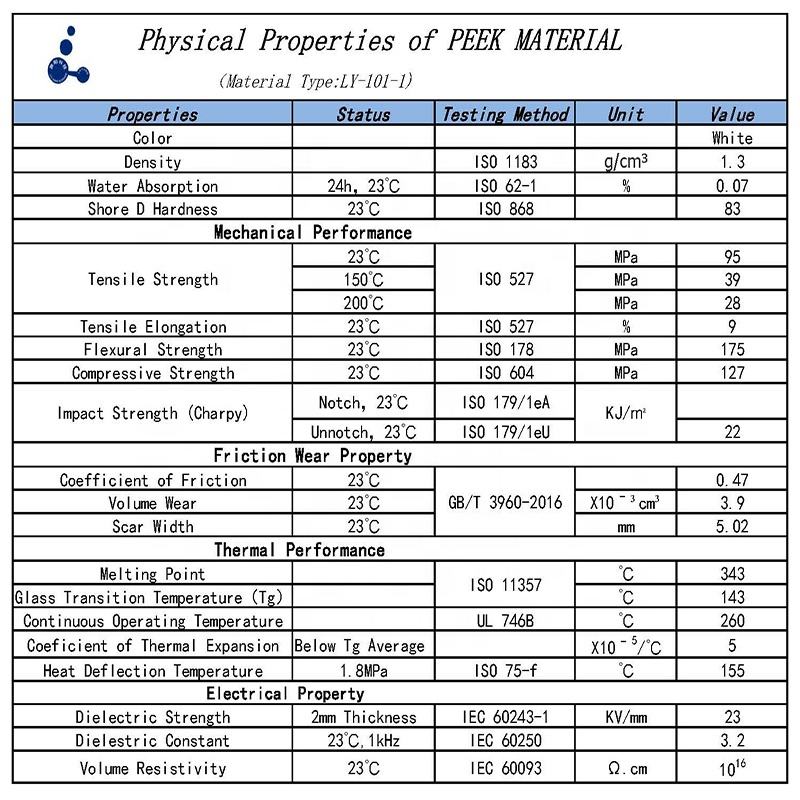

Material Properties

Mechanical Strength

PEEK has high tensile strength. Solenoid Valves PEEK can handle large pressure differences without deforming. This ensures long - term durability, like in high - pressure petroleum fluid control against flowing hydrocarbons. Mechanical integrity of PEEK electrical parts is key in tough environments.

Chemical Stability

PEEK resists many chemicals, such as strong acids, alkalis, and solvents. In chemical plants, PEEK modified solenoid valve parts stay intact with continuous corrosive exposure. This extends valve lifespan and cuts leak and failure risks. Chemical resistance makes PEEK electrical parts suitable for industries needing chemical compatibility.

Electrical Properties

PEEK offers excellent electrical insulation. For PEEK electromagnetism valve parts, it separates electrical components from fluids. In power plants with high - voltage systems, Solenoid Valves PEEK prevent electrical short - circuits, ensuring safe and efficient operation. Electrical insulation is a major factor in PEEK electrical parts' wide use in sensitive applications.

Manufacturing Process

PEEK pellets are melted at high temps and injected into molds for specific valve part shapes. This makes detailed PEEK modified solenoid valve parts. After molding, parts are machined to meet tight tolerances for a perfect fit in valve assemblies. Precision is vital for Solenoid Valves PEEK's best performance.

1. PEEK electrical parts have excellent corrosion resistance and wear resistance, which can effectively extend the service life of valves.

2. Solenoid Valves PEEK has excellent stability against temperature and pressure fluctuations, ensuring precise control.

3. The structural design of the Solenoid Valves PEEK is simple, convenient for cleaning and maintenance, and reduces operating costs.

4. The excellent insulation performance of Solenoid Valves PEEK reduces energy consumption, while the PEEK material can be recycled and reused.

PEEK modified solenoid valve parts are used in fields such as oil and gas, chemicals, electricity, pharmaceuticals, and others.

Continuous R&D innovation ensures that our products always maintain their industry position.