Securing and Supporting Rolling Elements: At the core of its function, the PEEK bearing material cage within Bearings with PEEK Cages serves as a safeguard for the rolling elements within a bearing. Whether it's a ball bearing or a roller bearing, the cage, characteristic of Bearings with PEEK Cages, keeps the rolling elements evenly spaced. This even spacing is crucial as it prevents the rolling elements from colliding with each other, which could lead to premature wear and failure of the bearing. For example, in high - speed machinery like turbines, where the rolling elements are spinning at extremely high revolutions per minute, the PEEK bearing cage in Bearings with PEEK Cages ensures that the balls or rollers maintain their proper position, allowing for smooth rotation.

Facilitating Smooth Operation: The cage, a key component of Bearings with PEEK Cages, also guides the movement of the rolling elements. It provides a controlled path for them to follow as the bearing rotates. In applications where the bearing is subjected to varying loads, such as in automotive engines during acceleration and deceleration, the PEEK cage in Bearings with PEEK Cages enables the rolling elements to adapt to these changes in load distribution. This results in a more stable and efficient operation of the bearing, reducing vibrations and noise levels.

Advantages of polyetheretherketone Bearing cage:

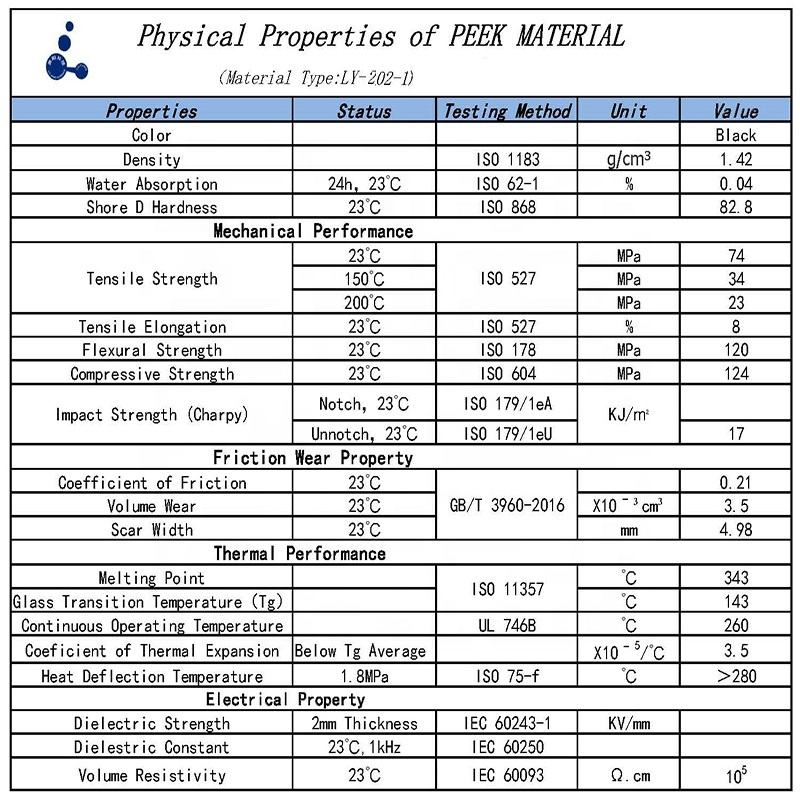

1. PEEK bearing material cage is made of high-strength materials, and the design focuses on lightweight, which can meet the requirements of high speed and high load.

2. The surface of PEEK bearing material cage has been specially treated and has good wear resistance and corrosion resistance, ensuring a long and stable service life.

3. PEEK bearing material cage has excellent thermal conductivity, which can effectively reduce the temperature inside the bearing and prevent bearing damage caused by overheating.

4. The installation and maintenance of PEEK bearing material cage are relatively simple, and if damaged, it can be easily replaced.

Details of polyethylene bearing cage::

Applications of polyetheretherketone Bearing cage:

1. Bearings with PEEK Cages of aircraft and spacecraft need to withstand extremely high loads and rotational speeds, and cages can provide stable support and protection.

2. Bearings with PEEK Cages in wind power generation, oil drilling and other fields need to withstand harsh environmental conditions, and cages can improve the stability and life of the bearings.

3. Automobile polyetheretherketone Bearing cages need to withstand large loads and impacts, and the cage can provide good support and protection.

4. polyetheretherketone Bearing cages in various mechanical equipment require cages to improve stability and life.

Why choose us:

1. We use high-quality materials and advanced processes to manufacture cages, and the products have excellent performance and stability.

2. We have rich experience and a professional technical team that can provide personalized solutions according to customer needs.

3. We value customer feedback and can respond quickly and provide timely technical support and services.