The PEEK cycloidal reducer is a cycloidal pinwheel reduction device with a PEEK composite material as its core transmission component. It combines the high load-bearing capacity of cycloidal transmission with the lightweight characteristics of PEEK material. The following details are provided in terms of structural principle, material advantages, performance parameters, and application scenarios:

1. Structural Principle

PEEK cycloidal reducer adopts a single-stage cycloidal pinwheel transmission structure: consisting of an eccentric input shaft, two PEEK cycloidal wheels with a phase difference of 180°, a steel pin gear housing, and an output mechanism. When the input shaft rotates, the eccentric sleeve drives the cycloidal wheel to perform planetary motion. The cycloidal wheel tooth profile meshes with the pin teeth on the pin gear housing, transmitting motion and power through the output shaft. The core innovation lies in the use of 40% carbon fiber reinforced PEEK injection molding for the cycloidal wheel and the PEEK-metal composite structure for the pin gear pin, achieving lightweight and self-lubrication of the transmission components.

2. Material Advantages

Lightweight Design: The density of the PEEK cycloidal reducer is only 1.45g/cm³, reducing the weight by 50%-60% compared to steel cycloidal wheels, and reducing the overall weight by more than 35%, especially suitable for robot joints with sensitive load requirements;

Toughness: The surface hardness of PEEK material reaches Rockwell hardness R120, combined with carbon fiber reinforcement, the tooth surface wear rate is only 1/5 of that of steel. It can still maintain long-term operation without lubrication under high-temperature conditions;

Temperature Adaptability: PEEK cycloidal reducer can work stably within a wide temperature range of -50℃ to 200℃, with a heat deformation temperature of up to 343℃, meeting the requirements of high-temperature industrial environments.

3. Core Performance Parameters

Reduction Ratio: 8:1 to 100:1 (single stage), supporting two-stage series connection to achieve higher reduction ratios

Rated Torque: 10 to 200N・m (corresponding models BX-25 to BX-100)

Transmission Accuracy: Return clearance ≤ 3 arc minutes, transmission efficiency > 95% (under rated conditions)

Life Index: Fatigue life under rated load > 8000 hours, impact load-bearing capacity is 3 times the rated torque

4. Typical Application Scenarios

Humanoid robot joints: Can be adapted to 50W to 5kW motors. With the internal and external shaft composite structure, it can reduce weight by 33%, torque density increases by 50%, suitable for complex motion scenarios such as fingers and knee joints that require both strength and flexibility.

Industrial robot auxiliary components: For light-load wrist joints of industrial robots or additional execution modules that need frequent start-stop and flexible turning, using PEEK cycloidal reducers can reduce the weight of non-core transmission parts and reduce maintenance downtime due to its fatigue resistance.

V. Application of Materials for Key Components

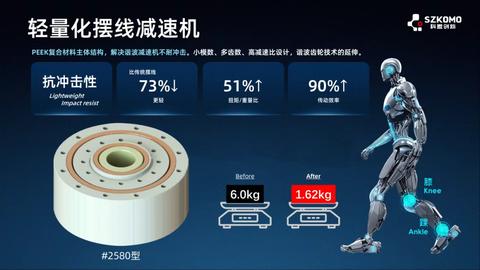

Spiral Bevel Gear: The spiral bevel gear is the core transmission component of the PEEK spiral bevel gear reducer. Using PEEK or carbon fiber reinforced PEEK to manufacture the spiral bevel gear can significantly reduce the weight while maintaining the transmission accuracy. According to public information, the PEEK lightweight spiral bevel reducer introduced by Komei Innovation has a spiral bevel gear that, through material innovation, increases the impact resistance of the reducer by 200% at a weight of 1.62 kg, meeting the high-load requirements of humanoid robots. At the same time, the fatigue resistance of PEEK helps extend the service life of the spiral bevel gear under high-frequency and alternating load conditions.

Pin Teeth: The pin teeth directly contact the tooth surface of the spiral bevel gear and require good wear resistance. Using PEEK-based composite material pin teeth or PEEK-coated metal pin teeth can take advantage of the low friction coefficient of PEEK to reduce the friction and wear on the tooth surface, possibly reducing the reliance on lubrication or allowing for simpler lubrication schemes. Additionally, its elastic property can buffer the impact of meshing, reducing operating noise.

Support and Sealing Components: The end cover, support ring, and other structural components of the reducer are made of PEEK material, which can reduce the weight of non-transmission core parts and achieve overall lightweighting. The PEEK-made seals can, with their advantages of high-temperature resistance and chemical corrosion resistance, prevent the leakage of lubricating oil inside the reducer and resist the erosion of harsh external environments, suitable for underwater, high-temperature, and other special scenarios for robot applications.

Advantages compared to traditional PEEK spiral bevel gear reducers

Outstanding lightweight performance: The density of PEEK is approximately 1.32 g/cm³, much lower than commonly used metal materials. Using PEEK to manufacture some parts can significantly reduce the weight of the reducer, lower the load on robot joints, improve motion flexibility and energy utilization efficiency, which is of great significance for humanoid robots that pursue high degrees of freedom and long battery life.

Optimized noise control: Due to the certain elasticity and self-lubrication property of PEEK, PEEK cycloidal reducer can effectively buffer the vibration generated by the meshing of the spiral bevel gear and pin wheel, thereby reducing noise and facilitating the use of robots in scenarios such as laboratories and medical environments that are sensitive to noise.

Enhanced environmental adaptability: PEEK has excellent chemical resistance and wide temperature range usage performance. In complex scenarios where traditional metal reducers are prone to failure due to high temperatures and chemical corrosion risks, reducers based on PEEK components can operate stably for a longer time.

Main application scenarios

Humanoid Robot Joints: The single-stage reduction ratio of the PEEK spiral bevel gear reducer can reach 87, and the double-stage can even exceed 3000. PEEK cycloidal reducer has high-load, high-precision characteristics. The lightweight PEEK version is suitable for joints such as the waist and hips, and lower limbs of humanoid robots that require both strength and weight sensitivity. According to research by Guoxin Securities, using the corresponding reducer for the lower limb joints can reduce the weight by 18% and improve control accuracy by about 3 times.

Special Robots: When used in special robots such as aerospace exploration and deep-sea research, the lightweight feature can reduce transportation and power costs, and the excellent environmental tolerance can ensure the reliable operation of the reducer in complex temperature and humidity conditions and the presence of chemical corrosive substances.