Introduction to PEEK Material Robot Sensors

PEEK (Polyether Ether Ketone) is a high-performance specialty engineering plastic with properties such as high temperature resistance (long-term service temperature around 240°C), chemical corrosion resistance, high strength, lightweight, low friction coefficient, and excellent electrical insulation. These advantages make it an ideal material for key components of robot sensors, addressing the shortcomings of traditional metal or ordinary plastic sensors in terms of precision, stability, and environmental adaptability.

I. Core Application Types and Characteristics

PEEK material mainly functions by manufacturing the core structural components or functional substrates of sensors. Common application types are as follows:

1. Six-Dimensional Force/Torque Sensors

Application Part: The "elastic body" (the core component for force signal perception) of the sensor.

Core Value: Traditional elastic bodies are mostly made of aluminum alloy, while PEEK has a better ratio of elastic modulus to density - ensuring structural strength while significantly reducing the mass of the elastic body, minimizing inertial interference during robot movement, and improving force measurement accuracy (up to ±0.1% FS) and dynamic response speed (response time < 1ms).

Typical Scenarios: Industrial robot assembly (such as precise screw tightening force control), collaborative robot human-machine interaction (such as collision force perception), medical robot surgical force feedback (such as bone surface grinding force monitoring in orthopedic robots).

2. Tactile/Strain Sensors

Application Part: The flexible substrate or electrode carrier of the sensor.

Core Value: PEEK has certain flexibility and fatigue resistance, allowing it to be processed into thin or irregular shapes, suitable for curved or flexible contact scenarios such as robot fingers and grippers; at the same time, its electrical insulation can prevent signal interference, ensuring the stability of tactile (such as pressure, texture recognition) or strain (such as joint deformation) data.

Typical Scenarios: Pressure perception in service robots when grasping fragile items (such as glass, fruits), strain monitoring for the fit in industrial robot flexible assembly.

3. Specialized Sensors for Corrosive Environments

Application Part: The housing, probe protection sleeve, or contact components of the sensor.

Core Value: PEEK has extremely strong resistance to acids, alkalis, organic solvents, and high-temperature steam (such as CIP cleaning in the food industry), far superior to stainless steel or ordinary plastics, protecting the internal components of the sensor from corrosion and extending its service life.

Typical Scenarios: Liquid level/concentration sensors in food/medical robots (such as monitoring the liquid level in sauce tanks), environmental parameter sensors in chemical robots (such as protecting corrosive gas detection probes).

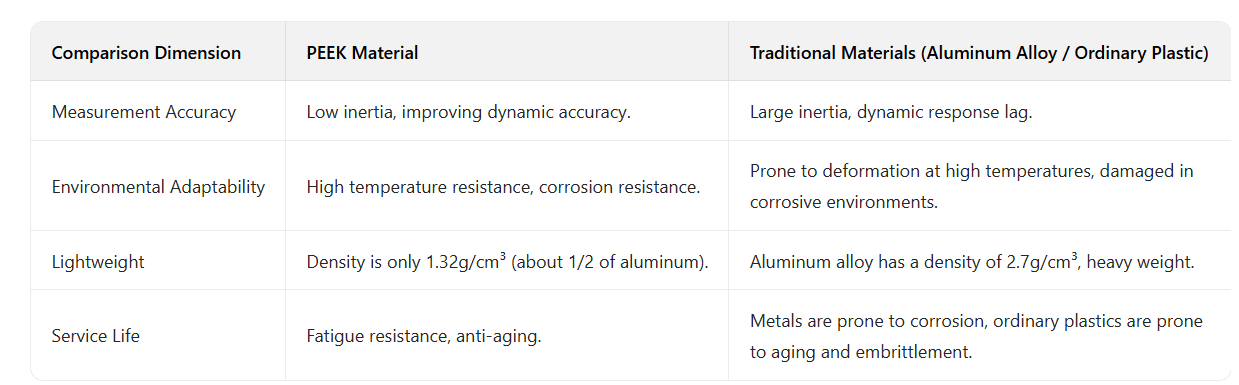

II. Core Advantages over Traditional Materials

III. Typical Application Fields

Industrial robots: Assembly force control, grinding force feedback, grasping pressure monitoring;

Medical robots: Force perception of surgical instruments (such as force feedback in laparoscopic operations), joint strain monitoring of rehabilitation robots;

Special robots: Corrosion-resistant environment sensors in food/chemical fields, temperature/force sensors in high-temperature conditions (such as automotive welding).