High - Temperature Resistance: PEEK allows the lip seal to work well in high - heat settings. In the energy industry, around steam turbines or hot pipelines, it can withstand temperatures that would damage other seals. This ensures reliable operation in tough thermal conditions.

Corrosion Resistance: PEEK is chemically inert. In chemical plants with aggressive chemicals like acids, alkalis, and solvents, the PEEK lip seal/PEEK lip sealing resists corrosion. It keeps its sealing performance, preventing leaks that could cause product contamination or environmental problems.

Wear Resistance: For applications with constant movement, such as rotating shafts, the PEEK lip seal /PEEK lip sealingstands up to repeated contact and fluid - borne particle abrasion. Its wear - resistant nature extends the seal's lifespan, cutting replacement frequency and maintenance costs.

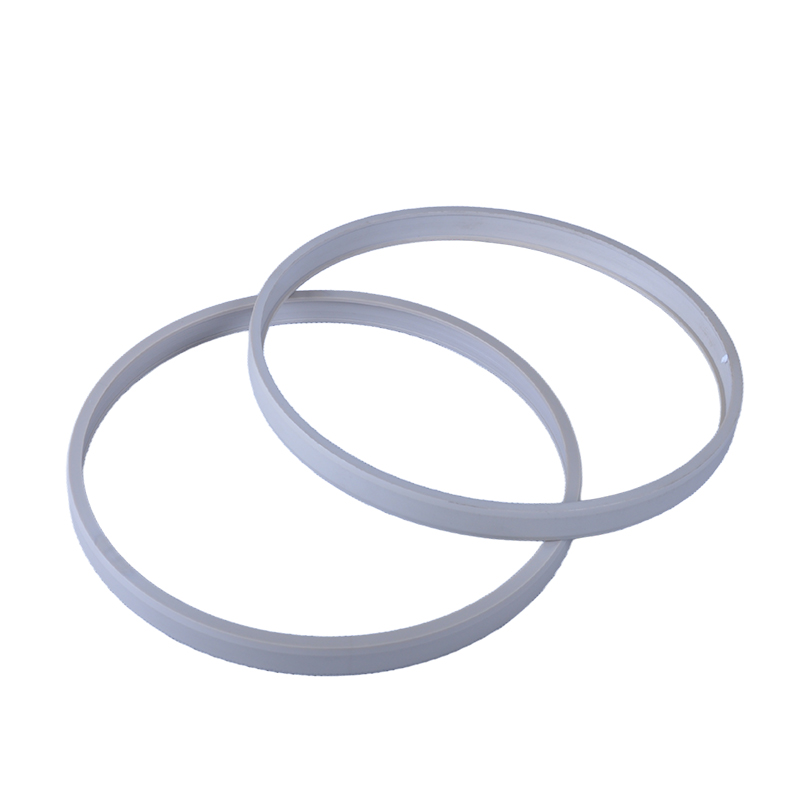

Lip - type Design: The single - lip seal's design is made for effective sealing. The PEEK shaft seal contacts the shaft tightly, forming a fluid - leak barrier. PEEK's flexibility lets the lip adapt to minor shaft irregularities, ensuring a good seal, especially in dynamic applications like pumps and motors.

Simple Structure: The PEEK lip seal/PEEK shaft seal has a simple structure, making it easy to install and maintain. Fewer components mean less complexity and a lower chance of malfunction. In food and pharma industries, this simplicity allows for quick servicing without sacrificing sealing performance.

Chemical Industry: In chemical processing equipment like reactors, distillation columns, and pipelines, the PEEK lip seal/PEEK lip sealing resists chemical corrosion and keeps a tight seal, ensuring safe and efficient chemical processes.

Pharmaceutical Industry: In pharma manufacturing, the PEEK lip seal /PEEK lip sealing prevents drug contamination. Used in valves, pumps, etc., it safeguards product quality and safety.

Food Industry: In food processing plants, the PEEK lip seal/PEEK shaft seal meets strict hygiene standards. Its wear and corrosion resistance, along with easy - to - clean structure, makes it suitable for food - handling machinery, maintaining food safety.

Energy Industry: In power plants and oil/gas facilities, the PEEK lip seal is used to seal components. Its high - temperature and wear resistance make it fit for high - pressure and high - temperature environments, ensuring reliable energy - equipment operation.

Advantages of PEEK lip sealing:

1. lip seal PEEK /PEEK shaft seal can maintain good mechanical properties at high temperatures.

2. lip seal PEEK/PEEK shaft seal has excellent corrosion resistance to most chemicals and can prevent seals from being corroded in chemical media.

3. lip seal PEEK/PEEK shaft seal has excellent wear resistance and can maintain a stable sealing effect under friction and wear conditions.

Application of PEEK lip sealing:

Lip seal PEEK ,PEEK shaft seal,is widely used in various occasions that require sealing, such as chemical, pharmaceutical, food, energy, etc. It can be used for sealing various pipelines, valves, pumps, reactors and other equipment, as well as for the production of various sealing grooves and gaskets.

Why choose us:

As a professional PEEK lip seal /PEEK shaft sealmanufacturer with years of production and research and development experience, we can meet the sealing needs of customers in various complex environments.

We focus on product quality and customer satisfaction, providing comprehensive after-sales service and technical support to ensure that customers have no worries during use.