Product technical parameters of peek Shaft End Comb Seal:

| Material Designation | LY-203-1 |

| Tensile Strength | 66MPa |

| Bending Strength | 114MPa |

| Compression Strength | 134MPa |

| Impact Strength (Unnotched) | 18J/P㎡ |

| Density | 1.44g/cm³ |

| Heat Distortion Temperature | >280℃ |

| Continuous Operating Temperature | 260℃ |

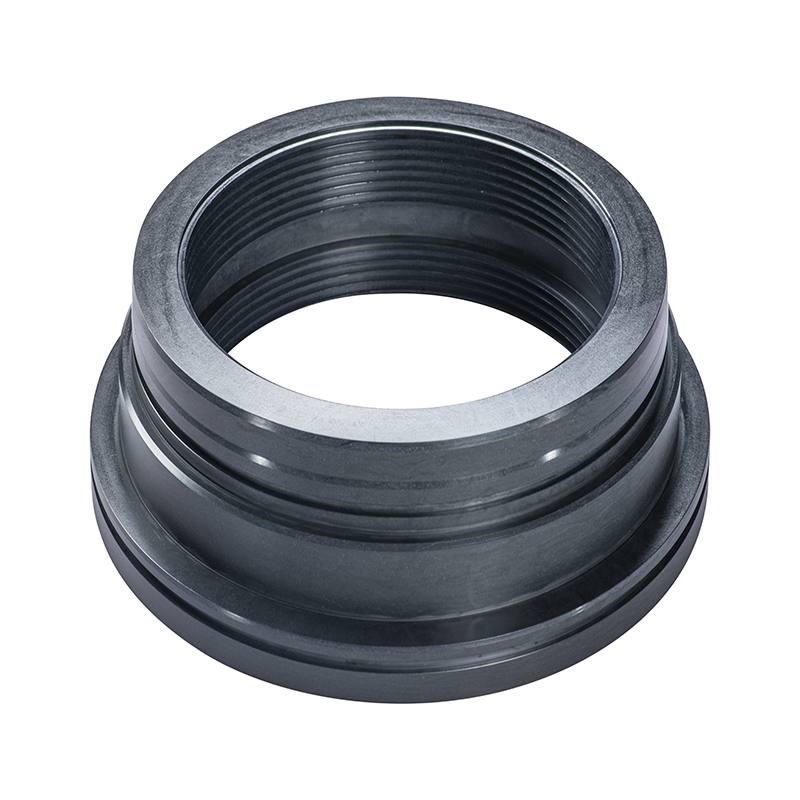

Product Introduction of Shaft End Comb Seal:

The Shaft End Comb Seal produced by our company is widely used in mechanical seals of various mechanical equipment in the fields of petroleum, chemical industry, electric power, metallurgy, light industry, textile, etc. The Shaft End Comb Seal adopts LY-203-1 labyrinth seal material, which is a special material for labyrinth seals. It has good self-lubrication and toughness, and can be used continuously at a temperature of 260°C. It has excellent wear resistance, scratch resistance, abrasion resistance, high temperature resistance and chemical corrosion resistance, and is suitable for demanding applications.

Product Advantages of peek Shaft End Comb Seal:

1. Shaft End Comb Seal has good sealing performance. It uses LY-203-1 labyrinth seal material, which is a special material for labyrinth seals. It can ensure the sealing effect of bearings or mechanical devices and prevent the leakage of liquids or lubricants. In industrial environments, Shaft End Comb Seal has high-quality sealing products that can maintain good performance under these extreme conditions and are not easy to deform or fail.

2. PEEK Shaft End Comb Seal is resistant to high temperature and high pressure and can be used continuously at a temperature of 260°C. The optimized structural design improves the efficiency of the compressor and has a long service life. It can reduce maintenance frequency and replacement costs, and improve the reliability and operating efficiency of the equipment.

3. PEEK Shaft End Comb Seal has good chemical stability and compatibility. It adopts a special molding process and has good chemical resistance. It is suitable for demanding applications. It can ensure that no chemical reaction or corrosion occurs under various working conditions and maintains stable performance.

Company Profile:

The company has strong R&D and design capabilities: it has jointly established a R&D center with Shanghai Jiao Tong University, Dalian University of Technology, Dalian University of Technology, and Jilin University. In 2019, the company was rated as Dalian Industrial Design Center.The company is the undertaker of the national "863" project; the setter of industry standards; and the 2022 Specialized and Special New Enterprise in Liaoning Province. It has a number of invention and utility model patents, filling many gaps in technology and products in this field in my country, and is a leading enterprise in this field.