Introduction to PEEK Carbon Fiber Sheet

Carbon fiber PEEK plates (also PEEK Carbon Reinforced Plate or Carbon PEEK plate) are composites made by combining PEEK resin and carbon fiber. This blend combines their best traits for an outstanding material.

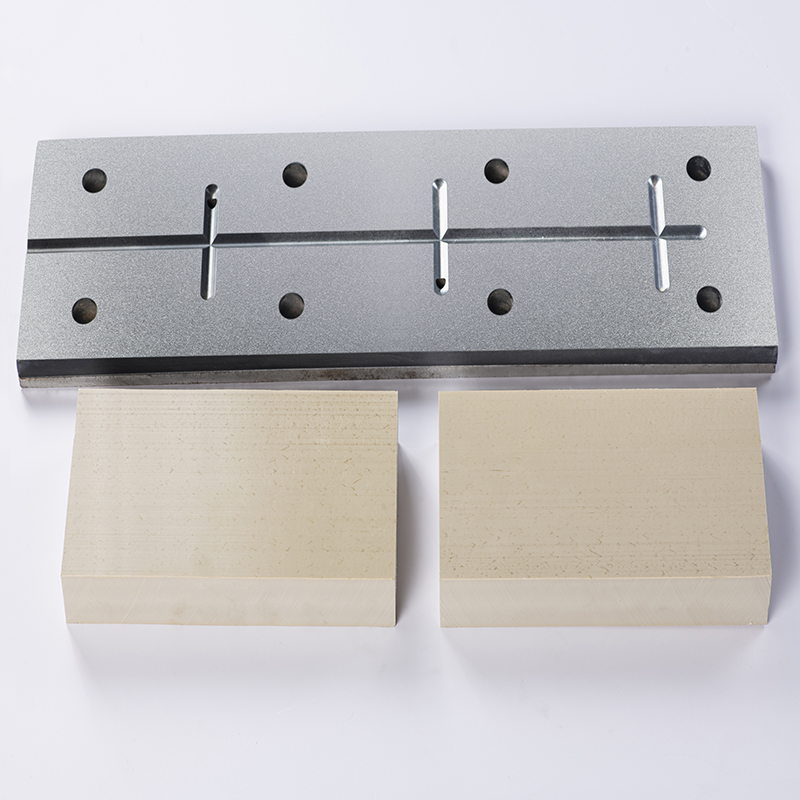

Manufacturing Process

High - quality carbon fibers, prized for their strength - to - weight ratio, are selected for these plates. They're pre - treated to better bond with PEEK resin. The melted resin is then evenly spread on the fibers. The fiber - resin mix is processed by compression molding (shaped under high pressure and heat) or autoclave curing (cured in a high - pressure, temperature - controlled chamber) to make top - quality plates with good mechanical properties.

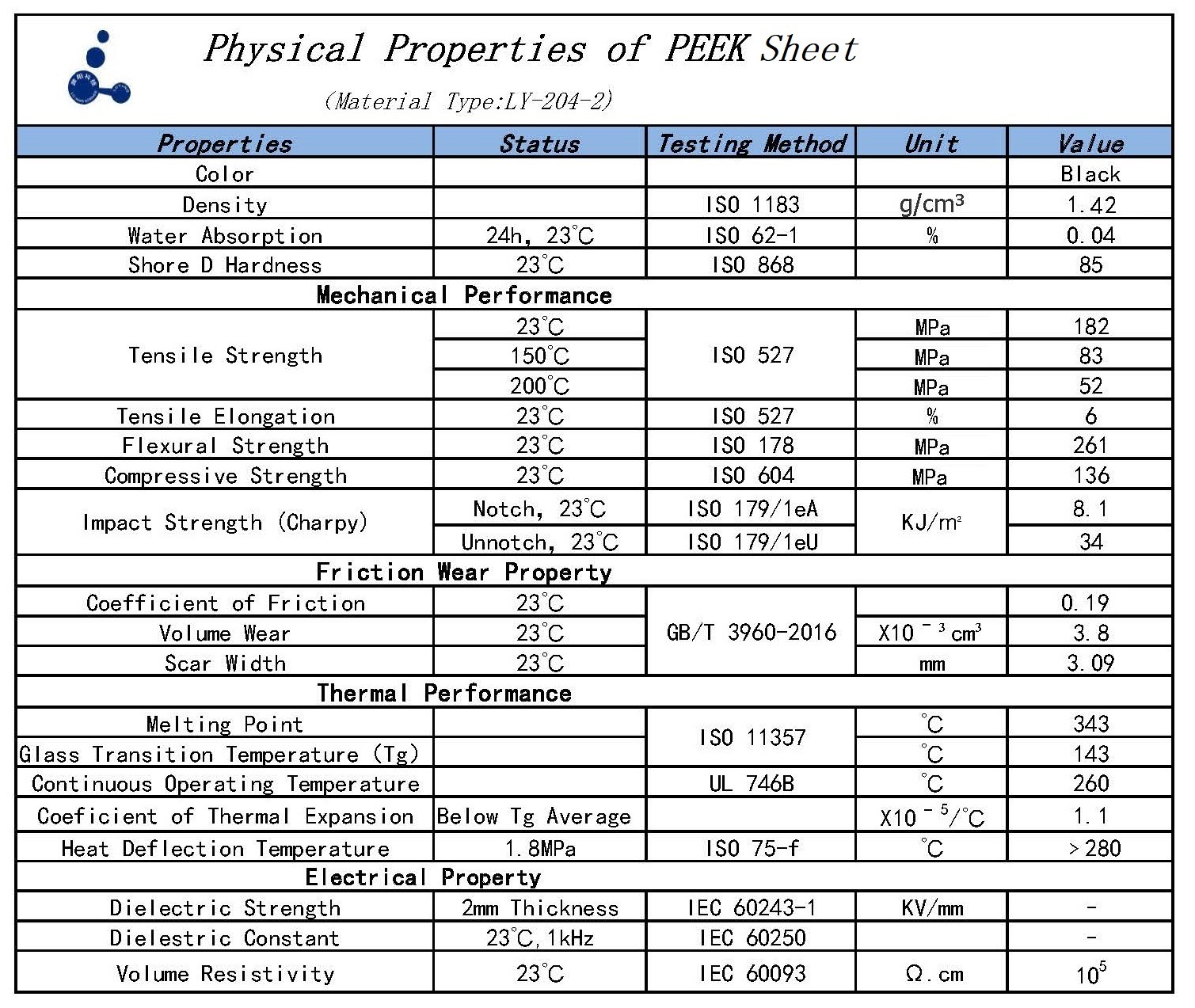

Material Properties

Exceptional Mechanical Strength

Carbon fibers in these plates bear most of the load. Combined with PEEK resin, the composite can withstand high tensile, compressive, and shear forces. This suits it for aerospace components like aircraft wings, which can endure flight forces without much deformation.

High Temperature Resistance

PEEK resin's heat resistance gets better with carbon fiber. These plates can work up to PEEK's glass transition temp (about 143°C), and sometimes higher briefly. This makes them great for industrial uses like automotive engine areas or high - temp furnaces.

Lightweight yet Strong

Carbon fibers add strength, while light PEEK resin cuts weight, giving a high strength - to - weight ratio. In cars, using these plates in body panels reduces weight without sacrificing safety or performance.

High Thermal Conductivity

Carbon fibers boost the composite's thermal conductivity. This helps with heat transfer, so the plates are useful as heat sinks in electronics to keep components cool and working well.

Low Expansion Coefficient

These plates have a low thermal expansion coefficient. In aerospace or electronics precision parts, they stay in shape across different temperatures.

Applications

Aerospace

In aerospace, these plates are used in aircraft wings, fuselages, and interiors. Their strength - to - weight ratio and heat resistance cut aircraft weight while keeping structural integrity. They can handle harsh flight conditions.

Automotive Manufacturing

In cars, they're used for lightweight, strong parts like body panels, suspension, and engine components. Their heat resistance is good for engine parts in high - temp areas.

Electronic Appliances

In electronics, they're used in heat sinks, circuit boards, etc. for their thermal conductivity and dimensional stability. Their light weight also helps in portable devices.

Petrochemicals

In petrochemicals, these plates are used in equipment in harsh chemical environments. Their chemical resistance and mechanical strength make them suitable for pipes, valves, and parts in contact with corrosive chemicals, and their heat resistance helps in high - temp processes.

1. PEEK Carbon Reinforced Plate(Carbon PEEK plate) has high tensile strength and bending strength, can withstand large loads and stresses, and maintains high rigidity and stability.

3. PEEK Carbon Reinforced Plate(Carbon PEEK plate) can be recycled and reused, meeting environmental sustainability requirements and reducing negative impact on the environment.

Carbon PEEK plate is often used in aerospace, automobile manufacturing, electronic appliances, petrochemical and other fields.