Introduction to PEEK Pure Resin Board

The Pure PEEK Sheet, made wholly of polyetheretherketone (PEEK) resin, is a high - performance polymer. Its remarkable properties have led to wide use across industries.

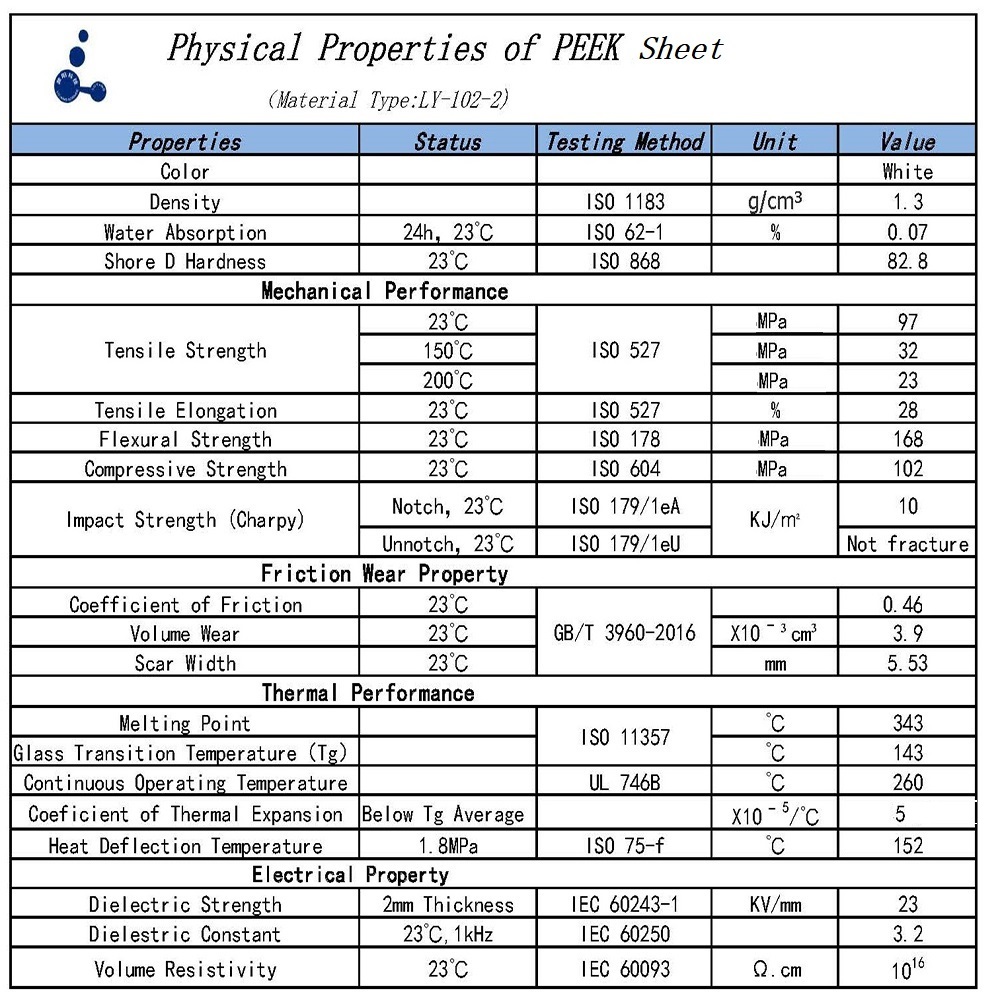

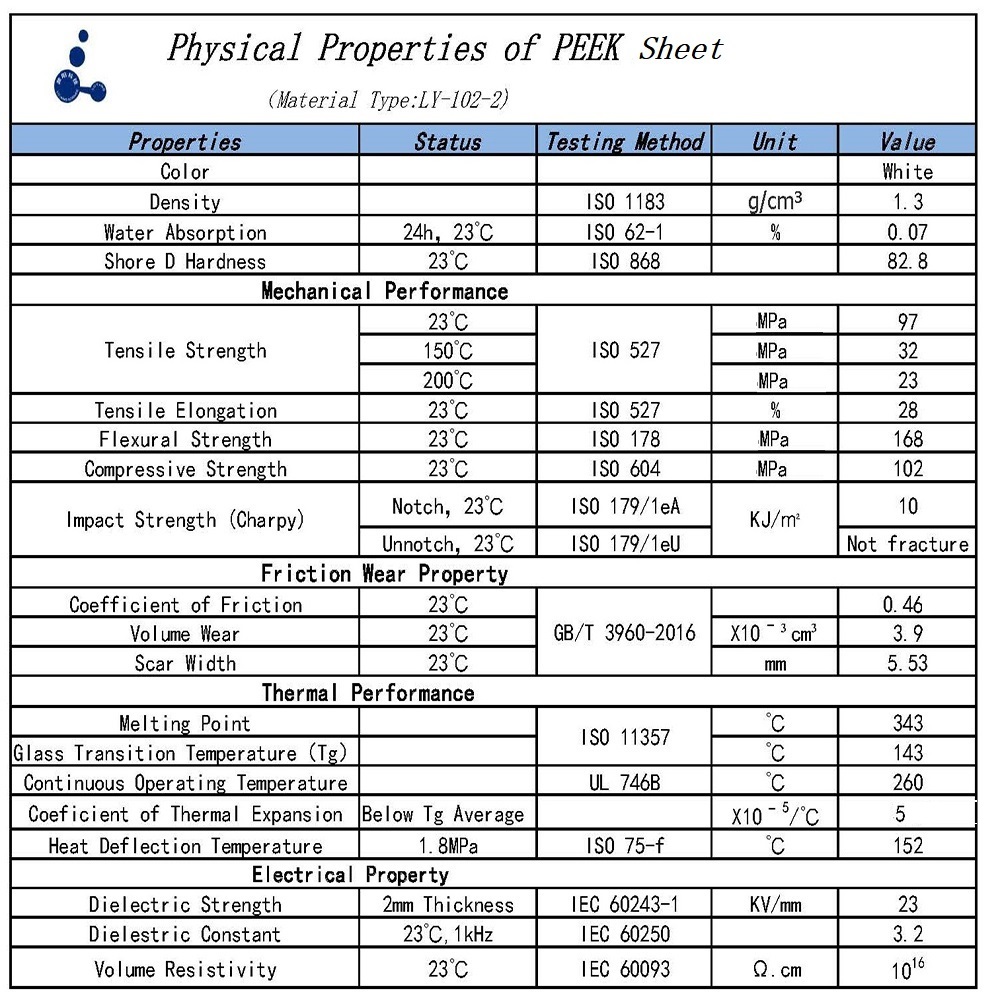

Material Properties

Exceptional High - Temperature Resistance

PEEK resin can endure high temperatures well. With a glass transition temp around 143°C and a melting point near 343°C, Pure PEEK Sheets keep structure and mechanical traits in hot settings. This suits aerospace uses, like engine compartments or near exhausts.

Superior Wear Resistance

These sheets show great wear resistance. Their molecular makeup gives high hardness and toughness, resisting abrasion and friction over time. In autos, they can be used in engine parts like piston rings or bearings to cut wear and extend part life.

Outstanding Corrosion Resistance

PEEK resists many chemicals, such as acids, alkalis, and organic solvents. Pure PEEK Sheets can face corrosive substances without much degradation. In the chemical industry, they're useful in pipelines, valves, and storage tanks dealing with aggressive chemicals, ensuring equipment works safely.

Good Electrical Insulation

As an insulator, Pure PEEK Sheets have excellent electrical properties. A low dielectric constant and dissipation factor prevent current flow and minimize signal interference. In electronics, they're fit for circuit boards, connectors, and insulating parts for reliable device function.

Manufacturing Process

Pure PEEK Sheets(PEEK Sheet Plate) are usually made by high - temperature extrusion or compression molding. In extrusion, PEEK resin pellets(PEEK Sheet Plate)are melted and pushed through a die to form a sheet of the right thickness. Compression molding involves putting PEEK resin in a mold and applying high pressure and heat to shape it. These methods ensure sheet uniformity and quality, allowing precise control of thickness, dimensions, and surface finish.

Applications

Aviation

In aviation, Pure PEEK Sheets(PEEK Sheet Plate) are widely used. They're used in aircraft interiors like cabin panels and seats for their light weight and heat resistance. They're also used in engine seals and gaskets, where heat and wear resistance are key for safe engine operation.

Electronics

In electronics, they're used in printed circuit boards (PCBs) as insulating layers, withstanding soldering heat. They're also in connectors and sockets, ensuring long - term reliable performance with their wear and electrical properties.

Automotive

In autos, they can be used in engine parts to cut wear and boost efficiency. They're also in automotive sensors, with chemical resistance and dimensional stability for accurate operation. They can make lightweight yet strong structural parts in high - performance vehicles.

Chemical Industry

In the chemical industry, Pure PEEK Sheets(PEEK Sheet Plate) are used in equipment handling corrosive chemicals. PEEK pipes(PEEK Sheet Plate) can carry aggressive fluids without corrosion, and valves and fittings made from these sheets control chemical flow, providing a long - lasting solution in chemical plants.

Advantages of PEEK pure resin board:

1. Pure PEEK Sheet has excellent insulation properties and can be used to make insulation materials.

2. PEEK Sheet Plate Compared with traditional metal materials, PEEK Sheet Plate is lighter and easier to transport and use.

3. PEEK Sheet Plate is easy to cut, drill, grind and bond, and has excellent processing performance.

Details of PEEK pure resin board:

Applications of Polyetheretherketone Board:

PEEK Sheet Plate is widely used in aerospace, automotive industry, electronics industry, chemical industry, medical equipment and other fields.

For example, in the chemical industry, Pure PEEK Sheet is used to manufacture chemical equipment such as pipes, valves, and pump bodies. In medical devices, Pure PEEK Sheet is used to manufacture medical devices and implants, such as artificial joints, dental implants, etc. Polyetheretherketone Board is also widely used in petroleum, energy, textile, food and other industries.

Why choose us?

We pay attention to environmental protection and sustainable development, and try to minimize the impact on the environment during production.

Our Polyetheretherketone Board is long-lasting and recyclable, helping to reduce resource waste and extend product lifecycle.

When you choose us, you not only get high-performance products, but you also contribute to the planet.