Introduction to PEEK Resin Pipe

PEEK pipe, or Polyether Ether Ketone Tube, is a high - performance piping option with multiple benefits, suitable for diverse industrial and specialized uses.

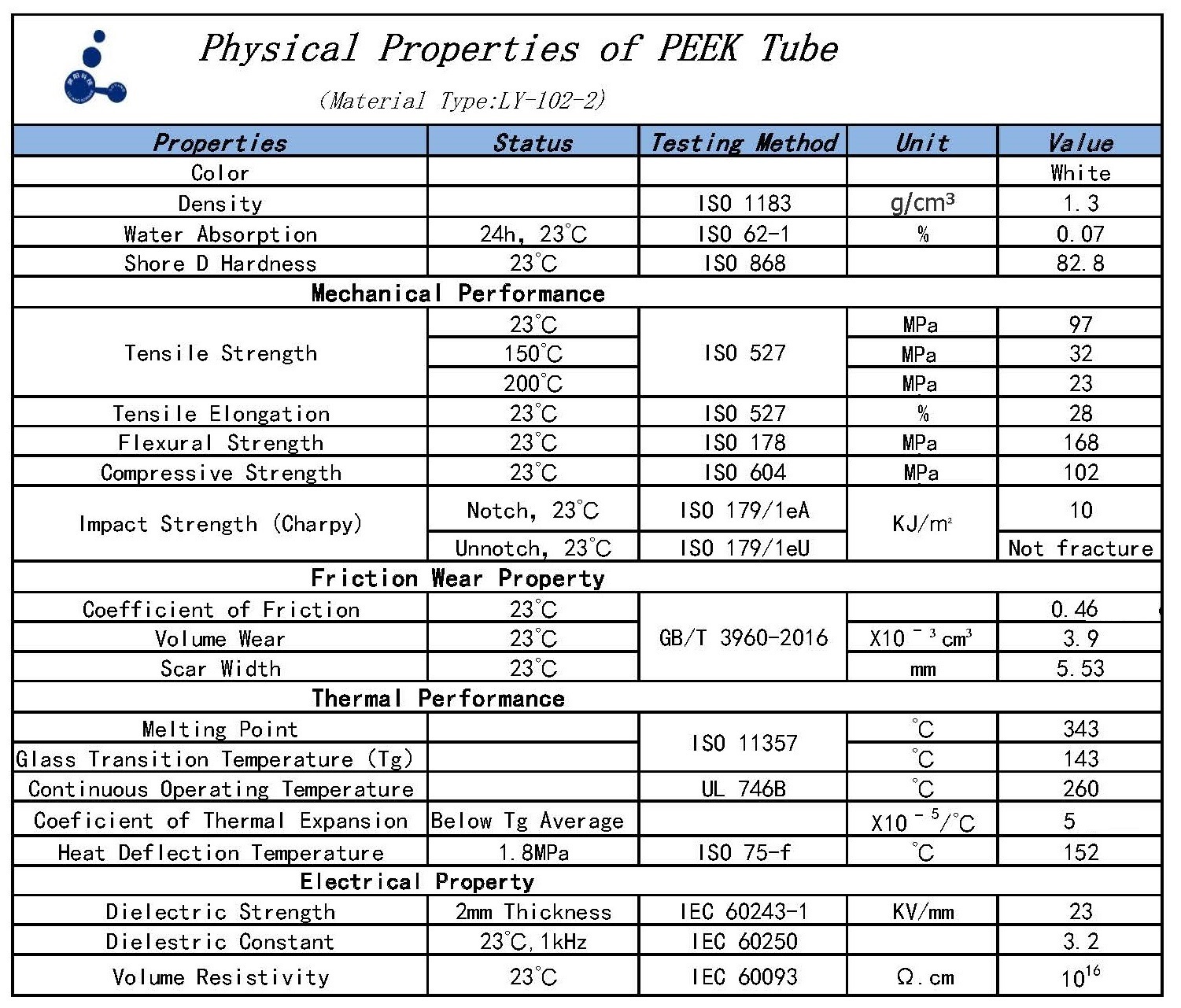

Toughness

PEEK pipe is tough and can endure substantial mechanical stress without breaking. In industrial setups, accidental impacts won't easily damage it, reducing leak risks and system failures related to the PEEK pipe.

Corrosion Resistance

The PEEK pipe has outstanding corrosion resistance, withstanding strong acids, alkalis, and organic solvents. This feature extends the piping system's lifespan and cuts maintenance costs in chemical processing plants where the PEEK pipe is commonly installed.

No Deformation or Cracking

PEEK pipes (Polyether Ether Ketone Tube)are dimensionally stable, not deforming under high pressure or temperature changes. In precision fluid transfer systems, they maintain shape for consistent performance. The absence of cracking in the PEEK pipe means no leakage, which is crucial in food and beverage industries.

Non - toxic and Odorless

Being non - toxic, the PEEK pipe(Polyether Ether Ketone Tube) is safe for transporting potable water, food, and medical fluids. Its odorless nature ensures no taste or smell transfer in relevant applications, making it ideal for food and beverage uses.

Long Service Life

Due to great mechanical and chemical properties, the PEEK pipe lasts long. In industrial installations like oil and gas pipelines, this long - lasting PEEK pipe reduces replacement frequency, minimizing downtime and costs.

Reusable

PEEK pipes can be cleaned and inspected for reuse, which is environmentally friendly and cost - effective, offering a sustainable solution. The reusability of the PEEK pipe is an added advantage for various industries that utilize it.

Good Mechanical Properties and Eco - friendly

These PEEK pipes have high tensile strength and stiffness to handle high - pressure fluid flow. Also, their processing produces no harmful pollutants, meeting strict environmental requirements.

In short, PEEK pipes, or Polyether Ether Ketone Tubes, are suitable for many applications where high performance, safety, and environmental compliance matter, from industrial to medical and food - related fields.

Advantages of PEEK resin pipe:

1.PEEK pipe has excellent corrosion resistance and can maintain the cleanliness of the pipeline for a long time.

2.PEEK pipe also has excellent toughness, can withstand various stresses and is not easy to break. In high-temperature, high-pressure, and highly corrosive environments, PEEK pipe can maintain good corrosion resistance and maintain the service life of the pipe for a long time.

3. PEEK pipe also has high strength and toughness, which can meet the requirements of large industrial equipment, such as boilers, pressure vessels, hoisting machinery, mechanical processing equipment, etc.

Details of PEEK pipe:

Applications of Lightweight Polymer pipe:

Lightweight Polymer pipe has a wide range of applications, including aerospace, automotive, electronics, medical and other fields. Lightweight Polymer pipe can be used to manufacture various industrial pipes, instrument pipes, valve pipes, pipe fittings, etc., and PEEK pipe is widely used in petroleum, chemical industry, metallurgy, electric power, construction, light industry, food, medicine, environmental protection and other industries.

Application cases of Polyether Ether Ketone Tube:

Deep sea oil and gas transmission pipes m-pipe and s-pipe are made of PEEK resin. This PEEK tube can withstand water pressure up to 104.425MPa and works normally on the seabed at a depth of 3000m. Under the same conditions, PEEK tube is 65% lighter than stainless steel pipes, 45% lighter than titanium alloy pipes, and 30% lighter than aluminum alloy pipes, which can significantly improve aircraft fuel efficiency and reliability.